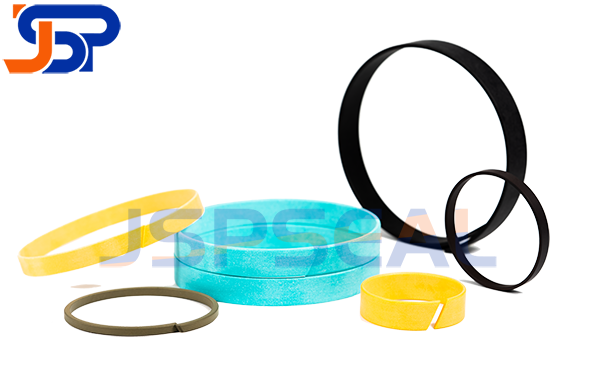

hydraulic wear rings - Manufacturers, Factory, Suppliers From China

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for hydraulic-wear-rings, wear ring, REPAIR KIT 0940691 E180 EL180, SEAL KIT 1289277, Pu Seal Hydraulic. We sincerely do our greatest to supply the very best support for every one of the purchasers and businessmen. As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world. Ptfe Bronze Piston Rings, KOMATSU SEAL KIT 707-99-14200, CH880 Crusher Accessories, Step Seal.Related Products

Top Selling Products

Leave Your Message