Hydraulic buffer seal rings are critical components in the maintenance and efficiency of various machinery. These kits help in damping and controlling the movement of hydraulic fluid, thereby protecting machinery from potential damage due to shocks and vibrations. An integral part of these kits, enhance performance by ensuring tight seals and reducing fluid leakage. Uniquely constructed to transmit pressure between main and buffer seals back to the system, these are interchangeable with standard PTFE buffer seals, offering versatility in applications. JSPSEAL, established in 1998, initially served the local earthmoving industry. By 2005, the company expanded with a new factory spanning over 10,000 square meters, equipped with advanced production lines and workshops, solidifying its position in the industry.

Understanding Hydraulic Buffer Seal Rings

Hydraulic Buffer Seal Rings: Managing System Shocks

A hydraulic buffer seal ring serves to absorb and manage the energy generated by shocks within hydraulic systems. These kits integrate multiple components that collectively enhance the efficiency and longevity of hydraulic machinery by mitigating the impact of pressure fluctuations and vibrations.

Components of a Hydraulic Buffer Seal Ring

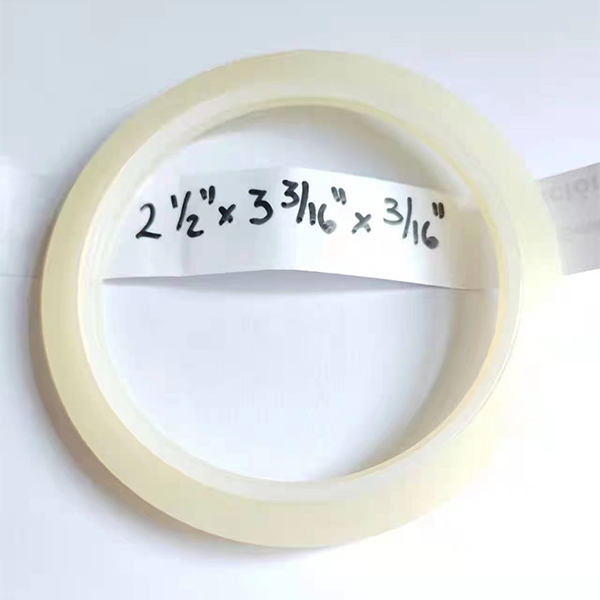

Typically, a hydraulic buffer seal ring includes essential components PU seal rings, and backup rings. Each component fulfills a critical role in safeguarding hydraulic integrity: seal rings prevent fluid leakage, buffer seals absorb kinetic energy during high-pressure operations, and backup rings prevent seal extrusion under extreme pressures.

The Crucial Role of Seal Rings

Seal rings are pivotal for the dependable performance of hydraulic systems. By preventing hydraulic fluid from escaping, seal rings maintain optimal pressure levels crucial for system functionality. Effective seal rings not only ensure operational efficiency but also minimize maintenance costs and reduce the risk of system failures by creating a secure seal between moving and stationary parts.

Buffer Seal Rings: Features and Benefits

Introduction to Buffer Seal Rings

Buffer seal rings are indispensable components within hydraulic setups, designed to bolster sealing capabilities and withstand substantial pressures. Often equipped with backup rings to prevent extrusion and bolster load-bearing capacity, their straightforward groove design facilitates effortless installation, adaptable to both open and closed grooves across diverse applications.

Defining Types and Availability

Available in various configurations such as single-lip and double-lip designs, buffer seal rings cater to diverse sealing requirements. These rings are crafted from materials chosen for specific hydraulic demands, including resilience to temperature extremes, chemical compatibility, and exceptional wear resistance.

Key Features of Buffer Seal Rings

Buffer seal rings boast features like outstanding wear resistance for prolonged service life and low compression-set attributes that preserve their efficacy over extended periods. Their material composition and design are meticulously selected to endure harsh operating conditions without compromising functionality, ensuring consistent performance in demanding environments.

Advantages of Buffer Seal Rings

Utilizing inch seal rings in hydraulic systems offers significant advantages, including heightened durability, minimized friction, and reliable prevention of leaks. Engineered to optimize sealing efficiency, these rings extend the operational lifespan of hydraulic components, curbing the frequency of maintenance and replacement due to wear and tear, thereby enhancing overall system reliability and efficiency.

Applications and Industries

Industries Leveraging Hydraulic Buffer Seal Rings

Hydraulic buffer seal rings play a pivotal role across diverse industries by significantly enhancing the durability and operational efficiency of hydraulic systems. Within manufacturing, they support various hydraulic presses and automation equipment, while in aerospace applications, they are critical components in landing gear and flight control systems. Across these industries, hydraulic buffer seal kits effectively absorb shocks and regulate fluid flow, contributing to more reliable and efficient machinery performance.

Specific Applications of Buffer Seal Rings

Buffer seal rings are tailored for environments that demand precise and robust sealing solutions. They excel particularly in high-pressure hydraulic systems essential for industrial manufacturing and heavy machinery operations. These rings also play a crucial role in precision machinery, including CNC machines and aerospace components, where maintaining impeccable seal integrity is essential for sustained accuracy and operational reliability. Their versatility and effectiveness underscore their vital role in modern technology across diverse applications.

Choosing the Right Buffer Seal Rings

Factors to Consider in Selection

Choosing the appropriate buffer seal rings involves careful consideration of several key factors. Size compatibility is paramount, ensuring a precise fit to prevent leakage and maintain system efficiency. Material selection is equally critical, with seals needing to withstand the specific pressures, temperatures, and chemical exposures typical in their operational environment. Additionally, understanding whether the application requires static or dynamic sealing informs the optimal design and performance expectations, ensuring the seals meet operational demands effectively.

Maintenance Tips for Longevity

To maximize the longevity and performance of buffer seal rings, adhering to proper installation and maintenance practices is essential. Careful installation techniques safeguard the integrity of the seals, preventing premature wear or damage. Regular maintenance routines should include periodic inspections to identify and replace worn-out seals promptly. Keeping seals clean and free from contaminants is crucial for preserving material integrity and ensuring consistent performance over time, thereby reducing the risk of unexpected failures.

Importance of Regular Inspections

Regular inspections are critical for proactive maintenance of hydraulic systems equipped with buffer seal rings. These inspections serve to detect early signs of wear, misalignment, or other potential issues that could compromise seal effectiveness and system performance. By implementing a structured inspection schedule and adhering to recommended maintenance protocols, operators can mitigate risks, prolong equipment lifespan, minimize downtime, and sustain optimal operational efficiency in their hydraulic systems.

Choose Quality Seal Kits for Efficiency and Savings

The combination of Hydraulic Seal Rings and Buffer Seal Rings enhances hydraulic system performance across industries by effectively managing fluid dynamics, absorbing shocks, and ensuring continuous machinery operation. Careful selection based on size, material durability, and environmental compatibility, along with regular maintenance practices, extends equipment lifespan and optimizes operational efficiency. These strategies effectively reduce downtime and deliver substantial cost savings for industries, bolstering productivity and reliability in hydraulic applications. Similarly, the JSPSEAL seal kit sets a new benchmark in aftermarket solutions by offering high-quality replacements for original parts at a reduced cost. This solution supports industries in maintaining efficient hydraulic systems across diverse applications, ensuring uninterrupted operations and minimizing operational expenses. By opting for JSPSEAL seal kits, businesses prioritize affordability while maintaining performance standards, underscoring their commitment to enhancing productivity and reliability in hydraulic machinery.