If you are in the hydraulic industry, you are probably familiar with hydraulic cylinder piston rods. These rods are essential components of hydraulic cylinders, which are used in a wide variety of applications, from construction and mining equipment to agricultural machinery and industrial machinery. In this article, we will provide an overview of hydraulic cylinder piston rods, including their manufacturing process, quality standards, and application and usage.

Hydraulic cylinder piston rods are typically made of high-strength steel alloys, such as 40Cr or 25Mn, and are designed to withstand high pressures and loads. The manufacturing process involves forging or casting the rod, followed by precision machining and surface treatment, such as hard chrome plating, to improve its corrosion resistance and wear resistance. China is a major producer of hydraulic cylinder piston rods, with many manufacturers offering a wide range of products and services to meet the needs of various industries.

If you are looking for hydraulic cylinder piston rods, it is important to consider factors such as quality, standards, and application requirements. China's hydraulic industry landscape is highly competitive, with many manufacturers offering similar products at different price points. It is important to work with a reputable supplier who can provide high-quality products that meet your specific needs and requirements. In the following sections, we will explore these topics in more detail and provide key takeaways to help you make informed decisions when it comes to hydraulic cylinder piston rods.

Key Takeaways

- Hydraulic cylinder piston rods are essential components of hydraulic cylinders used in various industries.

- The manufacturing process involves forging or casting, precision machining, and surface treatment.

- When selecting hydraulic cylinder piston rods, it is important to consider quality, standards, and application requirements.

Overview of Hydraulic Cylinder Piston Rods

Hydraulic cylinder piston rods are a fundamental component of hydraulic cylinders. They transmit the force created by the piston to the machine component doing the work. Understanding the function and importance of hydraulic cylinder piston rods is essential to ensure optimal hydraulic system performance.

Function and Importance

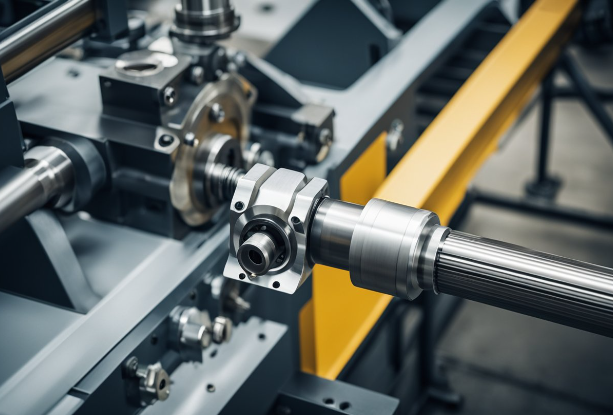

The function of hydraulic cylinder piston rods is to provide a mechanical connection between the piston and the load. They must be able to withstand the force created by the piston and transmit it to the machine component doing the work. The piston rod is typically a precision machined length of hard chrome plated cold finished steel bar. It is a critical component of every hydraulic or pneumatic cylinder.

Hydraulic cylinder piston rods play a vital role in maintaining the efficiency and performance of the hydraulic system. They must be designed to withstand the high pressure and stress that hydraulic systems generate. Failure of the piston rod can lead to system failure, downtime, and costly repairs.

Materials and Properties

Hydraulic cylinder piston rods are typically made of high-strength steel alloys, such as CK45, 4140, 5140, SS304, SS316, etc. The material used must be able to withstand the high pressure and stress generated by the hydraulic system. The piston rod must also be resistant to corrosion, wear, and fatigue.

The surface finish of the piston rod is also critical to its performance. A smooth surface finish is necessary to reduce friction and wear. The piston rod is typically hard chrome plated to provide a smooth, hard, and wear-resistant surface.

In conclusion, hydraulic cylinder piston rods are a critical component of every hydraulic system. Understanding their function and importance, as well as the materials and properties used in their construction, is essential to ensure optimal hydraulic system performance.

Manufacturing Process

When it comes to manufacturing hydraulic cylinder piston rods, there are several design considerations and fabrication techniques to keep in mind. In this section, we'll take a closer look at these factors to help you better understand the manufacturing process.

Design Considerations

Before beginning the manufacturing process, it's important to consider the design of the hydraulic cylinder piston rod. This includes factors such as the size and shape of the rod, as well as the materials used in its construction.

Commonly used materials for piston rods include CK45, 4140, 5140, SS304, and SS316. Raw material preparation and workblank production are the first steps in the manufacturing process. The workblank margin is determined according to the aspect ratio and the state of the workblank.

Fabrication Techniques

Once the design considerations have been taken into account, it's time to move on to the fabrication techniques. There are several techniques used in the manufacturing of hydraulic cylinder piston rods, including:

- Forging: This technique involves shaping the metal by heating it and then applying pressure to it.

- Machining: Machining involves removing material from a metal workpiece to create the desired shape.

- Grinding: Grinding is used to create a smooth surface finish on the piston rod.

After the fabrication techniques have been completed, the hydraulic cylinder piston rod is assembled and welded. There are two types of hydraulic cylinder piston rods: solid and hollow. Solid piston rods are made from a single piece of metal, while hollow piston rods are assembled and welded by the rod head, shaft, rod end, and oil inlet tube.

In conclusion, the manufacturing process for hydraulic cylinder piston rods involves careful consideration of design factors and the use of various fabrication techniques. By understanding these factors, you can ensure that your hydraulic cylinder piston rods are manufactured to the highest quality standards.

China's Hydraulic Industry Landscape

China's hydraulic industry has been growing rapidly in recent years, driven by the increasing demand for hydraulic systems in various industrial applications. In this section, we will take a look at some of the key manufacturers and market trends in China's hydraulic industry.

Key Manufacturers

China is home to many leading hydraulic cylinder and piston rod manufacturers. Some of the key players in the market include:

- Wuxi Gloria Industrial Tech Co.,Ltd.

- JW HYDRAULIC

- DALLAST Technology Co., Ltd.

- Jiangsu Huachen Hydraulic Co., Ltd.

- Ningbo Yinzhou Yongyi Machinery Co., Ltd.

These manufacturers offer a wide range of hydraulic cylinders and piston rods for various industrial applications, such as marine and offshore, water engineering, metallurgy, mining, wind power, construction machinery, environmental protection machinery, vehicles, machine tools, and agricultural machinery.

Market Trends

China's hydraulic industry is expected to continue growing in the coming years, driven by the increasing demand for hydraulic systems in various industrial applications. Some of the key market trends in the industry include:

- Rising demand for high-performance hydraulic systems: With the increasing demand for high-performance hydraulic systems, manufacturers are focusing on developing advanced hydraulic cylinders and piston rods that offer improved performance, reliability, and durability.

- Growing adoption of automation and robotics: The growing adoption of automation and robotics in various industrial applications is driving the demand for hydraulic systems that can deliver high precision and accuracy.

- Increasing focus on energy efficiency: With the increasing focus on energy efficiency, manufacturers are developing hydraulic systems that are more energy-efficient and environmentally friendly.

In conclusion, China's hydraulic industry is a dynamic and rapidly growing market, with many leading manufacturers offering a wide range of hydraulic cylinders and piston rods for various industrial applications. As the demand for hydraulic systems continues to grow, we can expect to see further innovation and development in this industry in the coming years.

Quality and Standards

When it comes to hydraulic cylinder piston rods, quality and standards are of utmost importance. In China, there are various certifications and compliance standards that manufacturers must adhere to in order to ensure that their products meet the required quality standards.

Certifications and Compliance

One of the most important certifications for hydraulic cylinder piston rods is the ISO 9001 certification. This certification ensures that the manufacturer has a quality management system in place that meets international standards. Additionally, some manufacturers may also have certifications specific to their industry, such as the API 5CT certification for the oil and gas industry.

In terms of compliance standards, manufacturers must adhere to various regulations and guidelines set by the Chinese government. For example, the GB/T 12337-2014 standard outlines the requirements for the design, manufacture, and inspection of hydraulic cylinders in China.

Testing and Quality Control

To ensure that hydraulic cylinder piston rods meet the required quality standards, manufacturers must conduct rigorous testing and quality control measures. This includes testing the materials used in the manufacturing process, as well as conducting non-destructive testing (NDT) to detect any defects or flaws in the piston rods.

Manufacturers must also keep detailed records of their testing and quality control measures, including material certificates and inspection reports. These records must be kept on file for at least three years in case of any issues or defects that may arise.

Overall, the quality and standards of hydraulic cylinder piston rods in China are closely monitored and regulated to ensure that they meet the required quality standards. By adhering to these standards and conducting rigorous testing and quality control measures, manufacturers can ensure that their products are of the highest quality and meet the needs of their customers.

Application and Usage

Industrial Applications

The China hydraulic cylinder piston rod is used in a variety of industrial applications such as construction machinery, metallurgy, electromechanical equipment, and packaging machinery. The piston rod is suitable for all kinds of different types of hydraulic cylinders, pneumatic cylinders, and engineering machinery.

The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the cylinder. The bore diameter of the hydraulic cylinder ranges from 40mm to 1200mm, and the rod diameter ranges from 12mm to 1000mm. The stroke is up to 15000mm, and the maximum working pressure is 700 bar.

Maintenance and Care

To ensure the longevity and optimal performance of your China hydraulic cylinder piston rod, it is important to perform regular maintenance and care. Here are some tips to keep in mind:

- Regularly check for any signs of wear and tear, such as scratches, dents, or corrosion.

- Keep the piston rod clean and free from debris or contaminants that could cause damage.

- Lubricate the piston rod with a high-quality lubricant to reduce friction and wear.

- Check the seals and gaskets for any signs of damage or leaks. Replace them if necessary.

- Avoid overloading the hydraulic cylinder beyond its rated capacity.

By following these simple maintenance and care tips, you can ensure that your China hydraulic cylinder piston rod operates at its optimal level and lasts for many years to come.