Injection seals are pivotal in industrial settings, safeguarding machinery integrity and efficiency by preventing fluid leakage from cylinders or pumps and thwarting contaminant ingress. These seals are indispensable for achieving peak performance. Tailored to meet precise operational requirements, customized seals bolster durability and dependability. Hydraulic seals, encompassing cylinder and shaft seals, play integral roles in diverse reciprocating applications that demand rigorous sealing standards. JSPSEAL, a prominent manufacturer and distributor, specializes in top-tier hydraulic seals, seal kits, and replacement OEM seals tailored for mobile applications, delivering flawless sealing solutions aligned with industry needs.

What is Customized Injection Seals

Definition and Function of Injection Seals

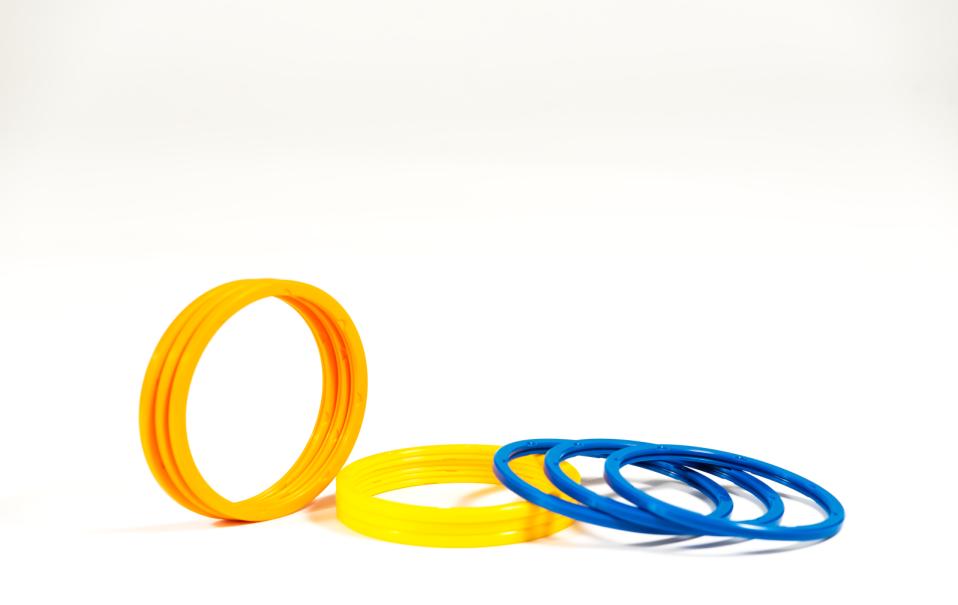

Injection seals are vital components within industrial machinery, meticulously engineered to prevent fluid leakage from cylinders or pumps while also shielding against external contaminants. By maintaining tight seals, these components uphold the operational efficiency and longevity of equipment across diverse industrial applications.

Importance of Customization in Industrial Applications

The customization of injection seals is paramount in meeting the precise requirements of industrial operations. Standard seals often fall short in addressing the unique demands of specialized machinery, potentially leading to operational inefficiencies and compromised performance. Tailored to exact specifications, customized seals significantly enhance durability, reliability, and overall performance, ensuring optimal functionality and extended service life.

Advantages of JSPSEAL's Customized Injection Seals

Overview of JSPSEAL as a Manufacturer

Founded in 1998, JSPSEAL initially provided service and maintenance solutions to the local earthmoving industry. By 2005, the company expanded with a new, expansive facility spanning over 10,000 square meters. This modern setup houses advanced production lines for injection molding and polyurethane pouring, complemented by dedicated workshops for mold and PTFE processing. Such comprehensive infrastructure empowers JSPSEAL to deliver high-quality injection seals with unmatched precision and efficiency.

Customization Capabilities and Expertise

Specializing in hydraulic seals, JSPSEAL offers an extensive range including PU rod seals, piston seals, buffer rings, wear rings, wipers, slide rings, and backup rings. These seals are crafted from diverse materials such as Urethane, POM, Nylon, Rubber, Metal Case, PTFE (Teflon), and Phenolic Resin Cotton Fabric. JSPSEAL's product lineup caters to aftermarket markets associated with leading brands like Caterpillar, Komatsu, Volvo, Doosan, Hyundai, Hitachi, Case, John Deere, XCMG, Sany, Sandvik, Metso, and ITM. The company's expertise in customization ensures that seals are precisely tailored from materials like TPU, PTFE, POM, Nylon, and Rubber, addressing the specific and varied needs of industrial applications with solutions that guarantee reliability and durability.

Customization Process at JSPSEAL

The customization process at JSPSEAL is methodical and client-centered, aimed at meeting the precise requirements of each industrial application.

Selecting Optimal Materials for Custom Seals

It begins with a detailed assessment of the client's needs, followed by the selection of optimal materials from a diverse range including Urethane, POM, Nylon, Rubber, Metal Case, PTFE, and Phenolic Resin Cotton Fabric. Utilizing advanced production facilities equipped with injection molding and polyurethane pouring lines, JSPSEAL ensures the creation of highly specialized seals.

Innovating Custom Seals with Advanced Production Technology

Further enhancing the process are in-house workshops dedicated to mold and PTFE processing, guaranteeing that every seal is manufactured to exact specifications and standards. This meticulous approach guarantees that each custom seal delivers optimal performance and longevity.

Performance Benefits

Improved Performance Metrics Due to Customized Seals

Customized seals from JSPSEAL significantly enhance performance metrics across various applications. With an extensive inventory of approximately 10,000 products ranging from 10mm to 2100mm, JSPSEAL provides a comprehensive selection to meet diverse customer needs. The choice of materials plays a crucial role in the success of seal installation, and JSPSEAL offers robust technical support in material selection and development. Through continuous testing and analysis of new materials, JSPSEAL ensures the durability and operational efficiency of its products. This ongoing innovation and customization result in seals that optimize equipment performance, minimize downtime, and extend machinery lifespan.

Specific Industries and Applications Where JSPSEAL's Seals Excel

JSPSEAL's customized seals excel across various industries and applications, delivering reliable solutions tailored to specific requirements. Industries such as earthmoving, construction, mining, and manufacturing benefit significantly from JSPSEAL's specialized products. Designed to withstand harsh environments and rigorous usage, these seals are ideal for heavy machinery and equipment prevalent in these sectors. Moreover, JSPSEAL's products cater to aftermarket markets, offering compatibility with leading brands such as Caterpillar, Komatsu, Volvo, Doosan, Hyundai, Hitachi, Case, John Deere, XCMG, Sany, Sandvik, Metso, and ITM. By providing high-quality, customized sealing solutions, JSPSEAL ensures exceptional performance and reliability in demanding industrial environments.

Customer Satisfaction and Case Studies

Testimonials from Satisfied Clients

"Our company has been relying on JSPSEAL for years, and their customized seals have consistently exceeded our expectations. Their attention to detail and quality craftsmanship have made a significant difference in our equipment's performance and durability." - John Smith, Operations Manager

"JSPSEAL's seals have been crucial in improving our operational efficiency. Their customization capabilities ensured a perfect fit for our specialized machinery, resulting in reduced downtime and enhanced productivity." - Emily Brown, Maintenance Supervisor

Case Studies Demonstrating Performance Improvements

- Case Study 1: Construction Industry

A construction company implemented JSPSEAL's customized seals in their heavy machinery. The seals improved hydraulic system efficiency by 15%, reducing maintenance costs and downtime.

- Case Study 2: Mining Sector

In the mining sector, JSPSEAL's seals were integrated into mining equipment. This led to a 20% increase in equipment uptime due to enhanced sealing performance and durability in harsh mining conditions.

Final Words

JSPSEAL is dedicated to delivering high-quality, customized injection seals that optimize industrial machinery performance. Through meticulous assessment of client needs and careful selection of materials, JSPSEAL crafts seals tailored precisely to each application's requirements. Their advanced production facilities and comprehensive in-house workshops further elevate the precision and dependability of their products. As a result, JSPSEAL's seals significantly enhance performance metrics by boosting durability, reducing downtime, and prolonging machinery lifespan. Client testimonials and industry case studies underscore the tangible advantages of JSPSEAL's personalized solutions. Whether in construction, mining, or other rigorous sectors, JSPSEAL's bespoke sealing solutions ensure reliable performance and durability, even in harsh environments. Opt for JSPSEAL to experience tailored, superior performance that meets the exacting needs of industrial applications.