If you're looking to improve the performance of your engine, one component you should consider upgrading is the piston ring kit. Piston rings are essential parts of an engine that help seal the combustion chamber, prevent oil from entering the combustion chamber, and transfer heat from the piston to the cylinder wall. A high-quality piston ring kit can help improve engine efficiency, increase horsepower, and extend the life of your engine.

There are several types of piston ring kits available on the market, including cast iron, ductile iron, and steel. Cast iron rings are the most common and are typically used in standard engines. Ductile iron rings are stronger and more durable than cast iron rings and are often used in high-performance engines. Steel rings are the strongest and most durable and are commonly used in racing engines. When choosing a piston ring kit, it's important to consider the type of engine you have, as well as your intended use for the vehicle.

Engine Piston Ring Kit Fundamentals

When it comes to building or rebuilding an engine, understanding the fundamentals of the engine piston ring kit is essential. In this section, we will cover the main components of a piston ring kit, the types of piston rings, and their functions.

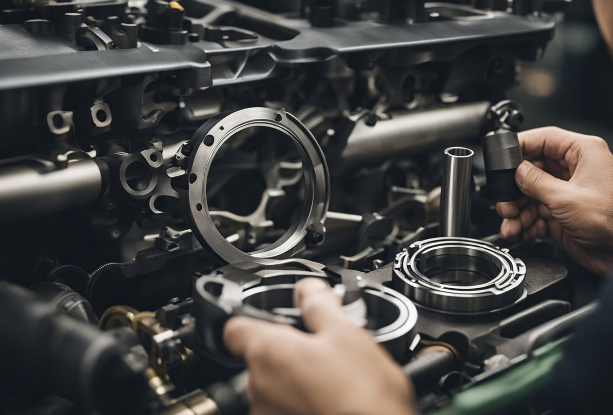

Components of a Piston Ring Kit

A typical engine piston ring kit usually includes three rings per piston: two compression rings and one oil control ring. The compression rings are responsible for maintaining a seal between the piston and cylinder wall, while the oil control ring regulates oil consumption and prevents oil from entering the combustion chamber.

Additionally, piston ring kits may also include other components such as piston pins, circlips, and locks. These components are crucial to the proper functioning of the piston and should be carefully inspected and replaced if necessary during engine assembly.

Types of Piston Rings

There are several types of piston rings available in the market, each with its unique characteristics and advantages. The most common types of piston rings are:

- Cast iron rings: These are the most common type of piston rings and are known for their durability and ability to withstand high temperatures.

- Steel rings: These rings are designed for high-performance applications and are known for their strength and ability to handle extreme heat and pressure.

- Chrome rings: These are typically used in high-performance engines and are known for their ability to reduce friction and wear.

- Moly rings: These rings are coated with molybdenum and are known for their ability to reduce friction and wear.

Functions of Piston Rings

The main function of piston rings is to maintain a seal between the piston and cylinder wall. This seal is crucial for maintaining proper compression and preventing oil from entering the combustion chamber.

In addition to maintaining a seal, piston rings also play a role in regulating oil consumption and reducing friction between the piston and cylinder wall. This is accomplished through the use of various coatings and materials that are designed to reduce wear and increase durability.

Overall, understanding the fundamentals of the engine piston ring kit is essential for anyone looking to build or rebuild an engine. By choosing the right type of piston rings and understanding their functions, you can ensure that your engine performs at its best and lasts for years to come.

Installation Guide

Preparation and Safety

Before installing the engine piston ring kit, it's important to take the necessary safety precautions. Make sure you have the proper tools and equipment, such as a ring compressor tool, piston ring pliers, and a torque wrench. Wear protective gear, including gloves and eye protection, to prevent injury from sharp edges or flying debris.

Be sure to clean the pistons thoroughly before installation to remove any debris or oil residue. Check the piston ring grooves for any damage or wear and replace the pistons if necessary. It's also important to check the manufacturer's specifications for the correct ring gap and orientation.

Step-by-Step Installation

- Begin by installing the oil ring. Using a proper ring installation tool, open the oil ring just enough to allow the ring to go over the top diameter of the piston. Work the opened ring down from the top of the piston to the oil groove. Place the ring squarely into the piston groove, taking care to keep it flat. Release the tension of the ring installer tool. (source: Hastings Piston Rings)

- Move on to the second ring. This gap should be 90-degrees from the oil ring scrapers, on the exhaust side. (source: Speedway Motors)

- Finally, install the top ring, which needs to be 180-degrees from the second ring, on the intake side. With the rings installed, the piston and rod is ready to be installed into the engine. (source: Speedway Motors)

- Follow the manufacturer's specifications for the correct torque sequence and values when installing the pistons and connecting rods.

Troubleshooting Common Issues During Installation

If you encounter any issues during installation, such as difficulty compressing the rings or improper ring gap, refer to the manufacturer's instructions or consult with a professional mechanic. It's important to address any issues before starting the engine to prevent damage or failure.

Material and Design Considerations

Materials Used in Piston Rings

When choosing a piston ring kit, one of the most important factors to consider is the material used in the rings. Piston rings are typically made from one of three materials: cast iron, ductile iron, or steel. Cast iron rings are the most common, and are known for their durability and resistance to wear. Ductile iron rings are more expensive, but offer improved strength and wear resistance. Steel rings are the most expensive, but offer the best performance in high-stress applications.

In addition to the base material, piston rings may also be coated with various materials to improve their performance. For example, chrome plating can improve wear resistance, while molybdenum can improve lubrication.

Design Features for Performance

In addition to the material used, the design of the piston rings can also impact their performance. One important design feature to consider is the width of the ring. Wider rings offer better sealing, but may also increase friction and wear. Thinner rings may offer better performance in high-stress applications, but may not provide as good of a seal.

Another important design feature to consider is the shape of the ring. Rectangular rings are the most common, but tapered rings can offer better performance in high-stress applications. Finally, the number of rings used can also impact performance. While most engines use two rings per piston, some high-performance engines may use three or even four rings for improved sealing and performance.

When choosing a piston ring kit, it is important to consider both the materials used and the design features of the rings. By selecting the right combination of materials and design features, you can ensure that your engine performs at its best and lasts as long as possible.

Maintenance and Care

Regular Maintenance Schedule

To ensure the longevity of your engine piston ring kit, it is important to follow a regular maintenance schedule. This includes regular oil changes, using high-quality engine oil, and proper engine assembly and maintenance. It is recommended to change your oil every 3,000 to 5,000 miles or as recommended by your vehicle manufacturer. Using high-quality engine oil can help reduce wear on the piston rings and prevent premature wear.

In addition, it is important to ensure that the piston ring gap and cylinder wall specifications are correct during engine assembly. This can help prevent premature wear and ensure optimal engine performance.

Best Practices for Longevity

To keep your engine running smoothly, there are several best practices for maintaining your engine piston ring kit. These include:

- Regularly check your engine oil level and top off as needed.

- Avoid harsh driving conditions, such as excessive idling or high-speed driving.

- Keep your engine clean and free of debris, such as dirt and dust.

- Avoid overloading your vehicle or towing more than the recommended weight.

- Regularly inspect your engine for signs of wear or damage, such as oil leaks or unusual noises.

By following these best practices, you can help ensure the longevity of your engine piston ring kit and prevent premature wear. It is also important to consult your vehicle manufacturer's recommendations for specific maintenance schedules and practices.