Hydraulic cylinder seals play a critical role in excavators, maintaining peak performance and preventing leaks that could hinder operational efficiency. As a prominent manufacturer specializing in hydraulic seals, JSPSEAL leverages more than ten years of export expertise, prioritizing quality and reliability in every product. Engineered to meet stringent standards, our solutions ensure prompt and reliable delivery. Rely on JSPSEAL for advanced seal technology that enhances the durability and functionality of hydraulic systems in excavators.

Understanding Excavator Hydraulic Cylinder Seals

Definition and Function

Excavator hydraulic cylinder seals are vital components designed to prevent hydraulic fluid leakage and ensure uninterrupted operational efficiency. These seals are manufactured from diverse materials such as polyurethane, rubber, or PTFE, selected based on specific operational conditions like seal type, pressure, fluid compatibility, speed, surface roughness, radial load, hydraulic shock, and temperature. Their primary role is to maintain the integrity of the hydraulic system, thereby promoting overall excavator performance and durability.

Importance of Quality Seals in Excavator Performance and Maintenance

High-quality hydraulic cylinder seals are indispensable for optimizing excavator performance while reducing maintenance costs. By effectively sealing hydraulic cylinders, these components safeguard against contaminants and minimize fluid loss. This protection translates into reduced downtime and operational disruptions, ultimately extending the equipment's service life and enhancing productivity.

Features and Benefits of JSPSEAL Excavator Hydraulic Cylinder Seals

- 1.Comprehensive Product Line

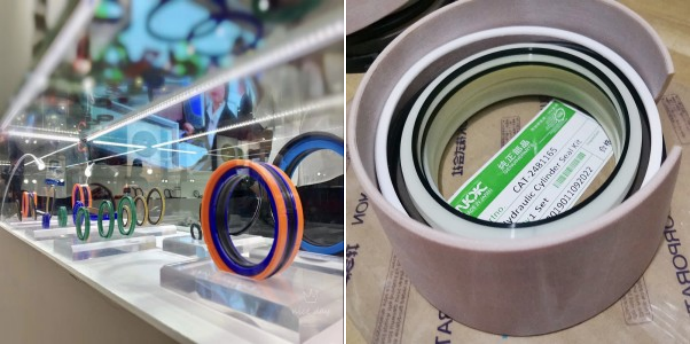

JSPSEAL offers an extensive array of hydraulic cylinder oil seals tailored specifically for excavators. Through the integration of advanced technologies from global sources, our product lineup includes specialized solutions such as Double Lip Oil Seals, Cushion Seals, and Bucket Seal Kits. These offerings are meticulously crafted to meet the rigorous demands of the excavation industry, ensuring reliability and performance under diverse operating conditions.

- 2.Material Quality, Durability, and Performance Specifications

At JSPSEAL, we prioritize superior material quality, durability, and performance in our hydraulic cylinder oil seals. Utilizing materials like urethane (TPU), PTFE bronze, NBR (Nitrile Butadiene Rubber), and phenolic resin cotton fabric, our seals deliver robust resilience in challenging environments. Each material is selected for its specific properties, ensuring prolonged service life and consistent performance across varying conditions.

- 3.New OEM Aftermarket Seal Kit

Our New OEM Aftermarket Seal Kit provides a cost-effective alternative to branded parts, offering direct replacements that meet or exceed OEM specifications. This kit facilitates seamless integration and dependable performance while significantly reducing costs. Customers can easily locate and procure the exact part they need by entering the part number on our user-friendly website, www.jspseal.com. For parts not listed, our dedicated team stands ready to assist in sourcing and customizing solutions to meet unique requirements.

- 4.Hydraulic Cylinder Seal Kit Components

Our Hydraulic Cylinder Seal Kits encompass a comprehensive range of components tailored for specific sealing applications:

- 1)Rod Seals: Available in urethane (TPU) with color options such as ivory, blue, and gray.

- 2)Buffer Seals: Offered in combinations like urethane+PA or PTFE Bronze+NBR, available in ivory and purple.

- 3)Wipers, Piston Seals, Wear Rings, and Backup Rings: Crafted from materials like phenolic resin cotton fabric or PTFE bronze, available in various colors.

- 4)O-Rings: Manufactured from NBR with a hardness of 90 Shore A, available in black.

These components underscore our commitment to delivering robust sealing solutions that effectively meet the diverse operational needs of the excavation industry. For further details or inquiries about our products, visit our website or contact our knowledgeable support team.

Common Challenges Addressed by JSPSEAL Seals

Typical Issues in Hydraulic Systems Without Proper Seals

Hydraulic systems in excavators face several challenges when not equipped with reliable seals. Common issues include:

- 1)Fluid Leakage: Without effective seals, hydraulic fluid can leak, leading to reduced system efficiency, contamination risks, and environmental hazards.

- 2)Wear and Tear: Inadequate seals can accelerate wear and tear on critical components like cylinders and pistons, resulting in increased maintenance costs and downtime.

- 3)Environmental Factors: Exposure to harsh environmental conditions such as extreme temperatures, moisture, and abrasive particles can compromise seal integrity, impacting overall system performance.

How JSPSEAL Seals Mitigate These Challenges

JSPSEAL hydraulic cylinder oil seals are engineered to address these challenges effectively:

- 1)Leakage Prevention: Our seals are designed with precise material compositions and sealing technologies to ensure tight, reliable sealing under varying pressures and temperatures. This prevents fluid leakage, maintaining system integrity and operational efficiency.

- 2)Wear Resistance: Utilizing high-quality materials like urethane (TPU), PTFE bronze, and phenolic resin cotton fabric, our seals offer exceptional wear resistance. They withstand friction and abrasion, extending component life and minimizing maintenance needs.

- 3)Environmental Durability: JSPSEAL seals are resilient against environmental factors such as temperature extremes and exposure to contaminants. This durability ensures consistent performance in diverse working conditions, enhancing reliability and longevity.

Application Areas and Industries

Industries and Applications

JSPSEAL excavator seals find application across various industries and specific use cases, including:

1.Construction: Used in excavators for earthmoving, digging, and construction site operations.- 2.Mining: Deployed in mining excavators for extracting minerals and heavy-duty operations.

- 3.Infrastructure Development: Applied in road construction, building foundations, and infrastructure development projects.

- 4.Forestry: Utilized in forestry equipment for clearing land and managing forest resources.

- 5.Utilities: Used in utility excavators for maintenance and repair of infrastructure such as pipelines and utility lines.

Specific Excavator Models and Systems

JSPSEAL products are compatible with a wide range of excavator models and hydraulic systems, including but not limited to:

- 1.CAT (Caterpillar): Compatible with various CAT excavator models, ensuring seamless integration and reliable performance.

- 2.Komatsu: Designed to fit Komatsu excavators, providing robust sealing solutions tailored to specific operational requirements.

- 3.Hitachi: Suitable for Hitachi excavators, enhancing efficiency and durability in demanding environments.

- 4.Volvo: Engineered to meet the sealing needs of Volvo excavators, optimizing productivity and reducing maintenance costs.

Maintenance Tips for Excavator Hydraulic Cylinder Seals

Best Practices for Extending Seal Lifespan

To maximize the lifespan of hydraulic cylinder oil seals, follow these best practices:

- 1.Regular Inspection: Conduct routine visual inspections of seals for signs of wear, damage, or leakage. Address any issues promptly to prevent further damage.

- 2.Proper Lubrication: Ensure seals are properly lubricated to reduce friction and wear. Use lubricants recommended by the equipment manufacturer.

- 3.Seal Protection: Shield seals from abrasive particles, moisture, and extreme temperatures to maintain their integrity and performance.

- 4.Operational Care: Operate excavators within specified parameters to minimize stress on hydraulic components and seals.

Importance of Regular Inspection and Replacement Intervals

Regular inspection and timely replacement of worn seals are crucial for:

- 1.Preventing Downtime: Proactively replacing seals reduces the risk of unexpected failures that can lead to costly downtime and operational delays.

- 2.Maintaining Efficiency: Fresh seals ensure optimal hydraulic system performance, preserving equipment efficiency and productivity.

- 3.Cost Management: Scheduled seal replacement minimizes long-term maintenance costs by avoiding extensive repairs and component replacements.

Why Choose JSPSEAL?

Company Overview

JSPSEAL combines extensive industry experience, commitment to quality, and exceptional customer service:

- 1.Experience: With nearly 20 years in the aftermarket, we specialize in providing seal kits tailored for challenging work conditions, ensuring reliable performance and durability.

- 2.Dimensional Accuracy: Our parts match OEM specifications precisely, facilitating easy identification, ordering, and seamless integration.

- 3.Competitive Pricing: We offer cost-effective solutions without compromising on quality, surpassing OEM parts in value.

- 4.Efficient Lead Times: Leveraging over a decade of export expertise, we guarantee fast and efficient delivery worldwide.

Customer Testimonials

"JSPSEAL's seals have been a game-changer for our fleet. They've cut our maintenance costs and downtime significantly."

"Impressed with the quality and reliability. JSPSEAL seals perform as well as, if not better than, OEM parts."

"Great value for money! Their seals have outlasted others we've tried, saving us time and money."

Upgrade Your Equipment with JSPSEAL

JSPSEAL leads the market in providing high-quality excavator hydraulic cylinder oil seals, renowned for enhancing equipment performance and durability in sectors such as construction, mining, and agriculture. With nearly two decades of expertise in the aftermarket, we guarantee seals that meet rigorous industry standards, emphasizing precision, premium materials, and cost-effectiveness. Our solutions effectively tackle common challenges like leakage and wear, substantially minimizing downtime and maintenance expenses. Supported by a solid reputation for customer satisfaction and extensive industry insight, JSPSEAL offers dependable sealing solutions that ensure optimal performance and prolonged equipment lifespan. Rely on JSPSEAL to uphold the efficiency and reliability of your machinery in the most demanding operational environments.