Fuel Injection Pump Use Seal O Rings: A Comprehensive Guide

If you're a vehicle owner, you're likely familiar with the fuel injection system. This system is responsible for delivering fuel to the engine in a precise and controlled manner. One of the key components of the fuel injection system is the fuel injection pump, which is responsible for pressurizing the fuel and delivering it to the injectors.

To ensure that the fuel injection pump operates efficiently and effectively, it's important to use high-quality fuel injection pump seal O-rings. These O-rings are designed to provide a secure seal between the fuel injection pump and the fuel lines, preventing fuel leaks and ensuring that the fuel is delivered to the engine at the correct pressure.

Using low-quality or worn-out fuel injection pump seal O-rings can result in a range of issues, including reduced engine performance, increased fuel consumption, and even engine damage. By using high-quality O-rings and ensuring that they are properly installed, you can help to keep your fuel injection system running smoothly and avoid costly repairs down the line.

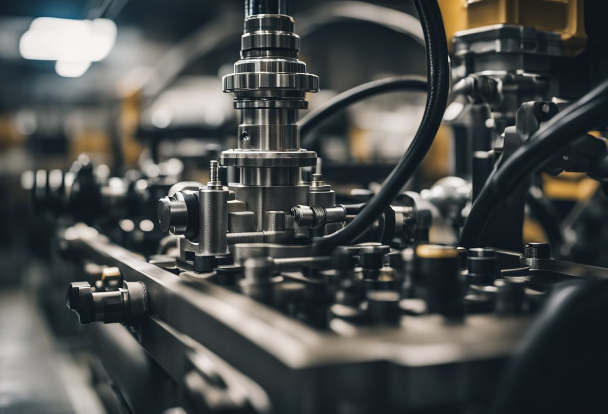

Basics of Fuel Injection Pump Technology

If you're looking to understand the basics of fuel injection pump technology, you've come to the right place. Fuel injection pumps are an integral part of modern engine systems, and they play a crucial role in ensuring that fuel is delivered to the engine in a controlled and efficient manner. In this section, we'll cover the evolution of fuel injection systems and the components of a fuel injection pump.

Evolution of Fuel Injection Systems

Fuel injection systems have come a long way since their inception, and today's systems are more advanced than ever before. The earliest fuel injection systems were mechanical, and they relied on a series of pumps, valves, and nozzles to deliver fuel to the engine. These systems were simple and effective, but they lacked the precision and control of modern systems.

Today's fuel injection systems are electronic, and they rely on a series of sensors, actuators, and computer algorithms to deliver fuel to the engine. Electronic fuel injection systems are more precise and efficient than mechanical systems, and they offer a range of benefits, including improved fuel economy, reduced emissions, and increased power output.

Components of a Fuel Injection Pump

Fuel injection pumps are complex devices, and they consist of a number of different components, each of which plays a crucial role in the functioning of the pump. Some of the key components of a fuel injection pump include:

- Plunger: The plunger is the main component of the fuel injection pump, and it is responsible for delivering fuel to the engine. The plunger is driven by a camshaft, and it moves up and down inside a barrel to deliver fuel to the engine.

- Barrel: The barrel is the part of the fuel injection pump that houses the plunger. The barrel is typically made of steel or cast iron, and it is designed to withstand the high pressure and temperatures associated with fuel injection.

- Delivery Valve: The delivery valve is responsible for controlling the flow of fuel from the fuel injection pump to the engine. The delivery valve is typically located at the bottom of the fuel injection pump, and it opens and closes in response to signals from the engine's electronic control module.

- Seal O-Rings: Seal O-Rings are used to prevent fuel leaks from the fuel injection pump. They are typically made of rubber or silicone, and they are designed to withstand the high pressure and temperatures associated with fuel injection.

In conclusion, fuel injection pumps are complex devices that play a crucial role in modern engine systems. By understanding the evolution of fuel injection systems and the components of a fuel injection pump, you can gain a deeper appreciation for the technology that powers today's engines.

Function of Seal O-Rings in Fuel Injection Pumps

Sealing Mechanisms and Materials

Fuel injection pumps are used in diesel engines to deliver fuel to the engine cylinders. The fuel injection pump consists of several components, including the fuel pump, fuel injectors, and seal O-rings. The seal O-rings are used to prevent fuel leaks and maintain proper fuel pressure.

The sealing mechanism of O-rings is based on the deformation of the ring when it is compressed between two surfaces. O-rings are made of various materials, including rubber, silicone, and Viton. The choice of material depends on the application and the operating conditions of the fuel injection pump.

Importance of Proper Sealing

The proper functioning of the fuel injection pump depends on the effectiveness of the seal O-rings. The failure of O-rings can lead to fuel leaks, which can result in engine damage, reduced performance, and increased emissions. Therefore, it is essential to use high-quality O-rings that are compatible with the fuel and the operating conditions of the fuel injection pump.

Proper installation of the O-rings is also crucial to ensure effective sealing. The O-rings should be inspected regularly for signs of wear, cracking, or damage. If any defects are found, the O-rings should be replaced immediately.

In conclusion, the seal O-rings play a critical role in the proper functioning of the fuel injection pump. The use of high-quality O-rings and proper installation and maintenance are essential to prevent fuel leaks and ensure optimal engine performance.

Installation of Seal O-Rings

Preparation and Precautions

Before installing the seal O-rings, make sure you have the correct replacement parts for your fuel injection pump. It is also essential to prepare the necessary tools for the installation process.

When handling the O-rings, it is crucial to avoid damaging them, as this can lead to fuel leaks and other problems. Ensure that your hands are clean and free of any contaminants, and use a suitable lubricant to prevent the O-rings from tearing.

Step-by-Step Installation Guide

- Begin by removing the old O-rings from the fuel injection pump. Use a suitable tool to pry them off gently, taking care not to damage the pump or surrounding components.

- Once you have removed the old O-rings, clean the fuel injection pump thoroughly. Use a suitable cleaning solution and a lint-free cloth to remove any dirt, debris, or old lubricant.

- Take the new O-rings and lubricate them with a suitable lubricant. Ensure that the O-rings are evenly coated with the lubricant, and avoid using too much, as this can cause the O-rings to slip out of place.

- Carefully install the new O-rings onto the fuel injection pump. Take care not to damage the O-rings or the pump during the installation process.

- Once you have installed the new O-rings, double-check that they are seated correctly and that there are no leaks.

By following these steps, you can ensure that your fuel injection pump's seal O-rings are installed correctly and will provide a reliable seal that prevents fuel leaks and other problems.

Maintenance and Troubleshooting

Regular Maintenance Schedule

To ensure your fuel injection pump continues to operate smoothly, it's important to follow a regular maintenance schedule. Here are some general maintenance tips:

- Check the fuel filter regularly and replace it as needed. A clogged filter can cause poor performance and damage to the fuel injection pump.

- Inspect the fuel lines for leaks and replace them if necessary.

- Keep the fuel injection pump clean and free of debris. Dirt and other contaminants can cause damage to the pump and decrease its efficiency.

- Use high-quality fuel to prevent buildup of deposits and other contaminants in the pump.

Common Issues and Solutions

Despite regular maintenance, fuel injection pumps can experience issues. Here are some common issues and their solutions:

- Leaks: Leaks can occur in the fuel injection pump due to worn out or damaged seals. If you notice a leak, it's important to address it promptly to prevent further damage. Replace the damaged seal with a new one to fix the leak.

- Poor Performance: Poor performance can be caused by a number of factors, including clogged fuel filters, dirty fuel injection pumps, and worn out injectors. Regular maintenance can help prevent these issues, but if you do experience poor performance, it's important to diagnose the root cause and address it promptly.

- Noisy Pump: A noisy fuel injection pump can be caused by a variety of factors, including air in the fuel system, a dirty fuel filter, or a worn out pump. Check the fuel lines and filter for any issues and replace them as needed. If the noise persists, it may be time to replace the fuel injection pump.

By following a regular maintenance schedule and addressing any issues promptly, you can ensure your fuel injection pump operates smoothly and efficiently.

Selecting the Right Seal O-Rings

When it comes to selecting the right seal O-rings for your fuel injection pump, there are a few key factors you need to consider. These include material compatibility and size and fit considerations. By taking these factors into account, you can ensure that you choose the right O-rings for your specific needs, which can help to prevent leaks and other issues.

Material Compatibility

One of the most important factors to consider when selecting seal O-rings for your fuel injection pump is material compatibility. O-rings can be made from a variety of materials, including rubber, silicone, and fluorocarbon, among others. Each material has its own unique properties, which can affect its compatibility with different types of fuels and other fluids.

When choosing O-rings, it's important to consider the specific type of fuel or fluid that your fuel injection pump will be exposed to. Different materials may react differently to different types of fuels, which can lead to premature deterioration or failure. By choosing O-rings that are compatible with the specific type of fuel or fluid you'll be using, you can help to ensure that your fuel injection pump operates smoothly and reliably.

Size and Fit Considerations

Another important factor to consider when selecting seal O-rings for your fuel injection pump is size and fit. O-rings come in a variety of sizes and shapes, so it's important to choose the right size and shape for your specific application. Choosing the wrong size or shape can lead to leaks or other issues, which can cause damage to your fuel injection pump or other components.

To ensure that you choose the right size and shape of O-rings, it's important to carefully measure the dimensions of your fuel injection pump and other components. You may also need to consult the manufacturer's specifications or other technical documentation to ensure that you choose the right size and shape of O-rings for your specific application.

Overall, selecting the right seal O-rings for your fuel injection pump is an important part of maintaining its performance and reliability. By considering factors such as material compatibility and size and fit, you can choose O-rings that are well-suited to your specific needs, which can help to prevent leaks and other issues.