Hydraulic Cushion Seals: What They Are and How They Work

If you work with hydraulic systems, you know that cushion seals are essential components that help prevent damage to your cylinders and other equipment. Cushion seals are designed to absorb shock and reduce vibration, which can extend the life of your hydraulic system and reduce the need for repairs. In this article, we'll take a closer look at hydraulic cushion seals and how they work.

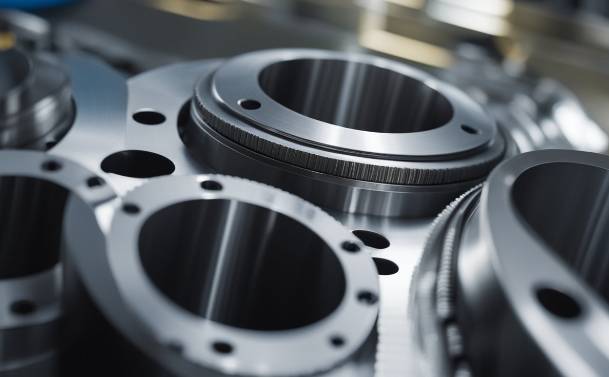

Hydraulic cushion seals are typically made of polyurethane or other durable materials that can withstand high pressure and extreme temperatures. They are installed in the cylinder head or piston and act as a buffer between the piston and the cylinder bore. When the piston reaches the end of its stroke, the cushion seal compresses to absorb the shock and prevent damage to the cylinder and other components.

In addition to protecting your hydraulic system, cushion seals can also improve performance by reducing noise and limiting the amount of fluid that is lost during operation. Whether you're working with heavy machinery or precision equipment, cushion seals can help ensure that your hydraulic system operates smoothly and reliably.

Fundamentals of Hydraulic Cushion Seals

Hydraulic cushion seals are an essential component of hydraulic cylinders. They are designed to control the deceleration of the piston as it approaches the end of its stroke, preventing excessive stress on the cylinder, seals, and other internal components. This controlled deceleration is critical to preventing premature failure and reducing the operational lifespan of the hydraulic system.

Material Composition

Hydraulic cushion seals are typically made from a variety of materials, including rubber, polyurethane, and PTFE. The selection of materials is critical to ensure that the seals can withstand the harsh operating conditions of hydraulic systems. For example, the seals must be able to withstand high pressures, extreme temperatures, and exposure to chemicals and other contaminants.

Rubber is a common material used for hydraulic cushion seals due to its excellent sealing properties and ability to withstand high pressures. Polyurethane is also a popular choice due to its durability and resistance to abrasion and chemicals. PTFE is used for applications that require high chemical resistance and low friction.

Design Principles

The design of hydraulic cushion seals is critical to their performance and longevity. The seals must be designed to provide a controlled deceleration of the piston, preventing excessive stress on the cylinder and other internal components. There are several design principles to consider when designing hydraulic cushion seals, including:

- Cushioning time: The cushioning time is the time it takes for the piston to come to a complete stop. This time must be controlled to prevent excessive stress on the cylinder and other internal components.

- Cushioning force: The cushioning force is the force required to decelerate the piston. This force must be carefully controlled to prevent excessive stress on the cylinder and other internal components.

- Seal geometry: The geometry of the seal is critical to its performance. The seal must be designed to provide an effective seal while also allowing for the controlled deceleration of the piston.

- Material selection: As mentioned earlier, the selection of materials is critical to the performance of hydraulic cushion seals. The materials must be able to withstand the harsh operating conditions of hydraulic systems.

In summary, hydraulic cushion seals are an essential component of hydraulic cylinders. They are designed to control the deceleration of the piston, preventing excessive stress on the cylinder and other internal components. The material composition and design principles are critical to their performance and longevity, and careful consideration must be given to these factors when designing hydraulic cushion seals.

Applications of Hydraulic Cushion Seals

Hydraulic cushion seals are essential components in various industrial and automotive systems. These seals play a crucial role in controlling the piston's deceleration and ensuring a smooth operation of the hydraulic cylinder. In this section, we will discuss the applications of hydraulic cushion seals in two main areas: industrial machinery and automotive systems.

Industrial Machinery

Hydraulic cushion seals are widely used in industrial machinery, particularly in heavy-duty applications. These seals are commonly found in hydraulic presses, injection molding machines, and metal-forming equipment. In these applications, the cushion seals help to reduce the impact of the piston on the cylinder's end cap, minimizing wear and tear on the hydraulic system's components.

In metal-forming equipment, hydraulic cushion seals are used to control the speed and pressure of the hydraulic cylinder. This helps to ensure consistent and accurate metal forming, reducing the risk of defects and product failure. In hydraulic presses, cushion seals are essential for controlling the force and speed of the ram, allowing for precise and repeatable pressing operations.

Automotive Systems

Hydraulic cushion seals are also used in various automotive systems, such as brake and suspension systems. In brake systems, cushion seals are used to control the rate of fluid flow, ensuring smooth and consistent braking performance. In suspension systems, cushion seals help to absorb shock and vibration, providing a comfortable ride for passengers.

Hydraulic cushion seals are also used in power steering systems, where they help to control the flow of hydraulic fluid, ensuring smooth and responsive steering. In addition, cushion seals are used in hydraulic lift systems, such as those found in car lifts and hydraulic jacks, to control the speed and force of the lifting mechanism.

In conclusion, hydraulic cushion seals are essential components in various industrial and automotive systems. These seals play a crucial role in ensuring the smooth operation of hydraulic cylinders, reducing wear and tear on the system's components, and improving overall performance and reliability.

Installation Guidelines

Surface Preparation

Before installing hydraulic cushion seals, it is important to prepare the surface to ensure proper adhesion and prevent leaks. The surface should be clean and free of any dirt, dust, oil, or other contaminants that may interfere with the seal's ability to adhere properly.

To prepare the surface, use a lint-free cloth to clean the area thoroughly. You can also use a cleaning solution recommended by the seal manufacturer. Be sure to follow the manufacturer's instructions carefully to avoid damaging the surface or the seal.

Seal Fitting Techniques

When fitting hydraulic cushion seals, it is important to use the correct technique to ensure a proper fit and prevent leaks. Here are some tips to keep in mind:

- Use the correct size seal for your application. Using the wrong size seal can result in leaks and other problems.

- Lubricate the seal and the mating surface with a compatible lubricant before installation. This will help the seal slide into place more easily and prevent damage during installation.

- Use a seal installation tool to ensure the seal is properly seated in the groove. Do not use a sharp tool or a hammer, as this can damage the seal and cause leaks.

- Make sure the seal is installed in the correct orientation. The seal should be installed with the lip facing the fluid and the spring facing away from the fluid.

By following these installation guidelines, you can ensure a proper fit and prevent leaks in your hydraulic cushion seals.

Performance and Maintenance

Operational Lifespan

Hydraulic cushion seals are designed to reduce the stress on the cylinder, seals, and other internal components, resulting in a longer operational lifespan. The right cushioning design is crucial to ensure the reliability, safety, and performance of hydraulic systems. The cushioning time is reduced up to 50%, permitting faster machine operating cycles for increased productivity. It also reduces machine noise for less downtime, which can lead to significant cost savings.

Selecting suitable types and materials for your seals is a matter of performance and safety. Making informed choices about your sealing solutions is paramount. You should consider factors such as the cylinder bore, rod diameter, and operating pressure when selecting the right cushion seal. It's important to choose a seal that can withstand the operating conditions and provide the right level of cushioning to protect your equipment.

Maintenance Best Practices

Proper maintenance of hydraulic cushion seals is essential to ensure their optimal performance and lifespan. Here are some best practices to help you keep your seals in good condition:

- Regularly inspect your hydraulic system for signs of wear and tear, such as leaks, cracks, or scratches on the seals.

- Clean the seals regularly to remove any dirt, debris, or contaminants that can cause damage.

- Use the right lubricant to ensure smooth operation and prevent seal damage. Avoid using incompatible lubricants that can cause swelling, cracking, or other forms of damage.

- Follow the manufacturer's recommendations for installation, operation, and maintenance of your seals. This can help you avoid common mistakes and ensure optimal performance.

By following these best practices, you can extend the lifespan of your hydraulic cushion seals and reduce the risk of costly downtime and repairs.

Challenges and Solutions

Common Failures

Hydraulic cushion seals are essential components of hydraulic cylinders that provide controlled deceleration of the piston as it approaches the end of its stroke. However, cushion seals are prone to several common failures that can lead to premature failure and reduced operational lifespan of the hydraulic cylinder.

One of the most common failures of hydraulic cushion seals is leakage. Leakage can occur due to several reasons such as worn-out seals, damaged cushion bushings, and particle contamination. Leakage can lead to reduced cushioning effectiveness and can cause excessive stress on the cylinder, seals, and other internal components.

Another common failure of hydraulic cushion seals is damage due to air in oil. Air in oil can cause significant damage to piston seals, resulting in moderate to extreme leakage. Air in oil can also cause damage to cushion bushings, resulting in a loss of cushioning effect.

Troubleshooting Tips

To troubleshoot hydraulic cushion seals, it is essential to identify the root cause of the failure. Here are some troubleshooting tips that can help you identify and resolve common failures of hydraulic cushion seals:

- Regularly inspect hydraulic cushion seals for signs of wear and tear, such as cracks or deformations. If you notice any signs of wear and tear, replace the seals immediately.

- Check for particle contamination in the hydraulic system. Particle contamination can cause significant damage to cushion bushings and seals. Use high-quality filters to keep the hydraulic system clean.

- Ensure that the hydraulic system is properly pressurized. Low pressure can cause the piston to move too slowly, resulting in a loss of cushioning effect.

- Check for air in oil. Air in oil can cause damage to piston seals and cushion bushings. Use high-quality hydraulic oil that is free from air.

By following these troubleshooting tips, you can identify and resolve common failures of hydraulic cushion seals, ensuring optimal performance and reliability of your hydraulic system.