If you work with hydraulic systems, you know how important it is to have reliable and efficient components. One of the most critical components of hydraulic cylinders is the piston rod seal. This small but crucial part plays a vital role in preventing fluid leakage and ensuring that your hydraulic cylinder operates smoothly and efficiently.

In this article, we will cover the basics of hydraulic cylinder piston rod seals, including the different types available and how to install and maintain them. We will also discuss the latest advancements in seal technology and how they can benefit your hydraulic system. Whether you are a seasoned professional or just starting with hydraulic systems, this article will provide you with the knowledge you need to make informed decisions about your piston rod seals.

Key Takeaways

- Hydraulic cylinder piston rod seals are critical components for preventing fluid leakage and ensuring efficient operation.

- There are different types of piston rod seals available, and choosing the right one depends on your specific application and operating conditions.

- Proper installation, maintenance, and troubleshooting can help extend the life of your piston rod seals and improve the performance of your hydraulic system.

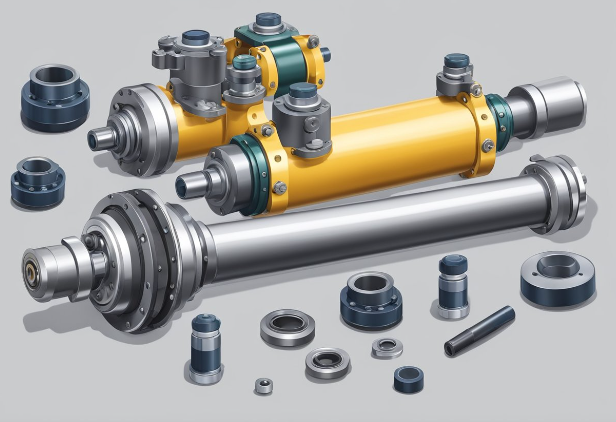

Basics of Hydraulic Cylinder Piston Rod Seals

Function and Importance

Hydraulic cylinder piston rod seals are essential components of a hydraulic cylinder. They serve two primary functions. First, they keep hydraulic fluid from leaking outside of the cylinder during operation. Second, they ensure that there is a thin layer of lubrication on the piston rod. This not only prevents corrosion but also lubricates other important parts of your cylinder.

The piston rod seal is crucial to the performance of your hydraulic cylinder. It keeps contact between the piston and the cylinder bore, helping to control the motion of your cylinder and keeping your cylinder at the same position when at rest, even when it's under a load. The seal formed by the piston seal is critical to the proper operation of the hydraulic cylinder. Piston seals can be either single- or double-action. A single-action piston has hydraulic pressure applied to only one side of the piston, while a double-action piston has hydraulic pressure applied on both sides.

Materials and Design

Hydraulic cylinder piston rod seals are typically made from materials such as polyurethane, rubber, or a combination of both. The material used depends on the specific application requirements, including the operating temperature, pressure, and the type of fluid being used.

Design considerations for hydraulic cylinder piston rod seals include the seal type, seal profile, and the size of the seal. The seal type refers to whether the seal is a lip seal, a V-ring seal, or an O-ring seal. The seal profile refers to the shape of the seal, and the size of the seal refers to its diameter.

It is essential to choose the right hydraulic cylinder piston rod seal for your application to ensure the proper operation of your hydraulic cylinder. A seal that is too soft may not provide adequate sealing, while a seal that is too hard may cause excessive wear on the piston rod. Therefore, selecting the appropriate material and design for your hydraulic cylinder piston rod seal is critical to ensure optimal performance and longevity of your hydraulic cylinder.

Types of Piston Rod Seals

When it comes to hydraulic cylinder piston rod seals, there are three main types: single-acting seals, double-acting seals, and rod wiper seals. Each of these types has its own specific function and design, making it important to choose the right type for your application.

Single-Acting Seals

Single-acting seals are designed for applications where pressure is applied on one side of the piston. These seals prevent leakage of hydraulic fluid from the cylinder. They are commonly found in hydraulic cylinders with piston rods and are available in a variety of materials, including rubber, polyurethane, and PTFE.

Double-Acting Seals

Double-acting seals are designed for applications where pressure is applied on both sides of the piston. These seals maintain a seal between the cylinder tube and piston, preventing the leakage of lubricants and gases. They are available in a wide range of compound and profile configurations to meet diverse applications, such as high and low temperatures and pressures, a wide variety of media, and harsh environments.

Rod Wiper Seals

Rod wiper seals are designed to remove contaminants from the piston rod as it retracts into the cylinder. These seals prevent dirt, dust, and other debris from entering the cylinder, which can cause damage to the piston rod and other components. Rod wiper seals are available in a variety of materials, including rubber, polyurethane, and felt.

When choosing a piston rod seal, it is important to consider factors such as the type of hydraulic fluid used, the operating temperature and pressure, and the duty cycle of the cylinder. By selecting the right type of seal for your application, you can ensure optimal performance and durability of your hydraulic cylinder.

Installation Guidelines

Proper installation of hydraulic cylinder piston rod seals is crucial to ensure their optimal performance and longevity. Here are some installation guidelines to follow:

Preparation and Cleaning

Before installing the piston rod seals, you need to ensure that the cylinder bore and piston rod are free from any debris, rust, or burrs that could damage the seal. Use a lint-free cloth or paper towel to clean the surfaces thoroughly. You can also use a mild solvent or brake cleaner to remove any stubborn contaminants.

Seal Orientation and Fitting

It is essential to install the seals in the correct orientation to prevent leakage and premature wear. The lip of the seal should face the pressure side of the cylinder. Additionally, make sure that the seals are not twisted or distorted during installation.

When fitting the seals, you can use a seal installation tool or a plastic mallet to avoid damaging the seal. Ensure that the seal is evenly and firmly seated in the groove. Use a depth gauge to check that the seal is installed to the correct depth.

In conclusion, following these installation guidelines will help ensure that your hydraulic cylinder piston rod seals perform optimally and have a longer lifespan.

Maintenance and Troubleshooting

Routine Inspection

Regular maintenance of hydraulic cylinder piston rod seals is essential to ensure their longevity and prevent costly downtime. You should perform a routine inspection of the seals to identify any potential issues before they become major problems.

During the inspection, you should check for signs of wear, damage, or leakage. Look for any scratches, nicks, or cracks on the piston rod surface, as well as any deformities or damage to the seals themselves. Check the seal gland for any signs of damage or wear, and ensure that the seal is properly seated in the gland.

Identifying and Addressing Leakages

If you notice any signs of leakage during your inspection, it is important to address the issue promptly to prevent further damage. The most common cause of leakage is a damaged or worn seal.

To replace a damaged seal, you will need to disassemble the cylinder and remove the old seal. Clean the seal gland thoroughly and inspect the piston rod for any damage or wear. Install the new seal carefully, ensuring that it is properly seated in the gland. Reassemble the cylinder and test it for leaks.

Another common cause of leakage is a damaged or worn piston rod. If the rod is damaged, it can cause the seal to wear prematurely and lead to leakage. In this case, you may need to replace the piston rod or have it repaired by a professional.

By performing routine inspections and promptly addressing any issues, you can ensure the longevity and reliability of your hydraulic cylinder piston rod seals.

Advancements in Seal Technology

Advancements in hydraulic cylinder piston rod seals have been made in recent years to improve the performance and longevity of these seals. Material innovations and design improvements have played a significant role in these advancements.

Material Innovations

New materials have been developed that offer improved resistance to wear, abrasion, and chemical degradation. One such material is polytetrafluoroethylene (PTFE), which is known for its excellent chemical resistance and low coefficient of friction. PTFE is often used in hydraulic cylinder piston rod seals to reduce friction and improve seal life.

Another material that has been developed is thermoplastic elastomer (TPE), which offers good chemical resistance and high elasticity. TPE is often used in hydraulic cylinder piston rod seals to provide a tight seal and prevent fluid leakage.

Design Improvements

Design improvements have also been made to hydraulic cylinder piston rod seals to improve their performance and reliability. One such improvement is the use of multiple sealing lips, which can provide better sealing performance and reduce the risk of fluid leakage.

Another design improvement is the use of asymmetrical sealing profiles, which can provide better sealing performance and reduce friction between the seal and the piston rod. This can lead to improved seal life and reduced maintenance costs.

In addition, new manufacturing processes have been developed that allow for tighter tolerances and more precise machining of hydraulic cylinder piston rod seals. This can lead to improved seal performance and longer seal life.

Overall, these advancements in seal technology have led to improved performance and reliability of hydraulic cylinder piston rod seals. By using these new materials and design improvements, hydraulic systems can operate more efficiently and with less downtime.