The D61EX-12 and D61PX-12 Bulldozer models from KOMATSU® excel in diverse earthmoving tasks, known for their robust performance. Featuring advanced hydraulic systems, they deliver efficient power and precise control. Key to their reliability is the hydraulic system, which relies on essential seals such as the KOMATSU® Part Number 707-99-35170. Regular upkeep of these seals is critical to prevent leaks, maintain operational efficiency, and prolong the lifespan of vital components. By opting for high-quality seal kits that meet OEM standards, operators ensure these bulldozers perform reliably across various operational environments.

Understanding the Hydraulic System of D61EX-12/D61PX-12

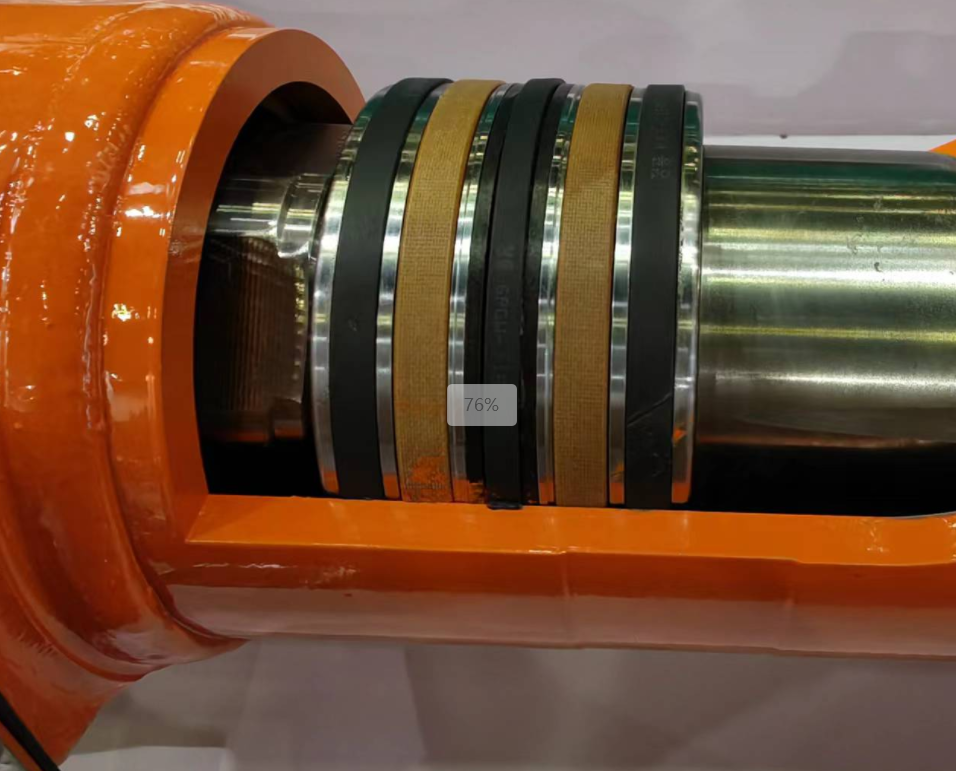

Hydraulic Cylinder Components

The hydraulic system of the D61EX-12/D61PX-12 Bulldozer models revolves around the hydraulic cylinder, a pivotal component that drives the bulldozer blade. Comprising the piston, rod, and cylinder barrel, this robust assembly is engineered to withstand high pressures and provide precise control across diverse terrain types.

Function of Hydraulic Seals

Hydraulic seals, exemplified by the KOMATSU® Part Number 707-99-35170, play a crucial role in maintaining peak performance. These seals effectively contain hydraulic fluid within the cylinder, preventing leaks that could diminish efficiency and potentially harm equipment. By ensuring a secure seal, hydraulic seals uphold consistent pressure levels, promoting reliable operation and reducing the need for frequent maintenance.

Importance of Hydraulic Cylinder Seal Kits

Role of Hydraulic Cylinder Seal Kits

Hydraulic Cylinder seal kits are crucial for preserving the integrity of hydraulic cylinders in heavy-duty machinery like the D61EX-12/D61PX-12 Bulldozers. These kits contain specialized seals that effectively seal hydraulic cylinders, preventing fluid leakage and contamination. By maintaining a secure seal, these kits ensure dependable operation and extend the equipment's operational lifespan.

Benefits of High-Quality Seals

Utilizing high-quality seals within hydraulic cylinder seal kits offers substantial benefits. Firstly, they enhance durability, capable of withstanding the rigorous conditions encountered in construction and earthmoving tasks. This durability reduces the frequency of seal replacements, thereby minimizing downtime and lowering maintenance costs. Secondly, high-quality seals optimize performance by reducing friction and wear within the hydraulic system, promoting smoother operation and maintaining consistent hydraulic pressure. By improving seal performance, operators can boost overall equipment efficiency and productivity, ensuring the bulldozer performs reliably across diverse operational environments.

Features of the D61EX-12/D61PX-12 Hydraulic Cylinder Seal Kit

Detailed Description of Components

The D61EX-12/D61PX-12 Cylinder Hydraulic Cylinder Seal Kit includes a comprehensive array of components essential for maintaining hydraulic integrity and performance in bulldozer operations:

- 1.Rod Seals and Buffer Seals: Manufactured by NOK, SKF, or H605, these seals are made from urethane (TPU) in colors like ivory, blue, or gray.

- 2.Piston Seals: Provided by JSPSEAL, these seals combine urethane with PA or PTFE, sometimes incorporating bronze or NBR, in colors such as ivory, purple, brown, blue, or yellow.

- 3.Wipers: JSPSEAL wipers are designed from urethane or NBR with metal components, available in colors like brown, blue, or yellow.

- 4.Wear Rings: These components from JSPSEAL feature a blend of materials such as urethane and metal or NBR and metal, colored in brown, green, or gold.

- 5.Backup Rings: Available in PTFE with bronze, NBR with PA or nylon, or other configurations, these rings come in black, white, or brown.

- 6.O-Rings: JSPSEAL supplies NBR O-rings with a hardness of 90 Shore A, uniformly black in color.

Compatibility

The seal kit is specifically designed to be compatible with the hydraulic systems of the following bulldozer models:

- CRAWLER DOZERS, D61EX-12, ANGLE (PAT)

- CRAWLER DOZERS, D61PX-12, ANGLE (PAT)

Description of KOMATSU® Replacement Seal 707-99-35170

This replacement seal is meticulously engineered to meet the exacting standards of KOMATSU®, ensuring optimal performance and durability in hydraulic applications. It is specifically tailored for use in the D61EX-12 and D61PX-12 Bulldozer models, providing reliable sealing to maintain hydraulic efficiency under varied operating conditions.

All manufacturer's names, part numbers, and descriptions are used for reference purposes only. We do not imply that any part shown is the product of these manufacturers. We also do not imply that the list price shown is exactly that of the manufacturer.

Benefits of Using Genuine Seal Kits

Advantages of OEM or Genuine Replacement Seal Kits

Choosing OEM or genuine replacement seal kits like those offered by JSPSEAL provides numerous advantages:

- 1.Experience: With nearly 20 years in the aftermarket, JSPSEAL understands the precise seal kit requirements for machinery operating in challenging environments.

- 2.Dimensional Accuracy: Each part maintains the same part number as OEM equivalents, ensuring ease of identification and procurement.

- 3.Cost-Effectiveness: Despite offering competitive pricing, JSPSEAL maintains the highest quality standards in its parts, ensuring reliability and longevity.

- 4.Lead Times: Leveraging over 10 years of export experience, JSPSEAL guarantees efficient shipping and delivery, minimizing downtime and operational delays.

Long-Term Cost Savings and Reduced Downtime

By using genuine seal kits, operators benefit from reduced maintenance costs and minimized downtime. These kits ensure reliable performance, extending the operational lifespan of hydraulic systems and optimizing overall equipment efficiency in demanding operational settings.

Installation and Maintenance Tips

Installing the Hydraulic Seal Kit

- 1.Prepare the Cylinder: Thoroughly clean and inspect the hydraulic cylinder.

- 2.Seal Placement: Ensure precise alignment when installing each seal and component from the kit.

- 3.Assembly: Reassemble the hydraulic cylinder components as per manufacturer specifications.

- 4.Testing: Perform a pressure test to validate seal integrity and system functionality.

Maintenance Best Practices

- 1.Regular Inspections: Periodically check seals for wear, damage, or leaks.

- 2.Fluid Quality: Use clean hydraulic fluid to prevent contamination and prolong seal life.

- 3.Operating Conditions: Monitor pressures and temperatures to prevent extremes that could affect seals.

- 4.Timely Replacement: Replace worn seals promptly to prevent equipment damage and minimize downtime.

Customer Testimonials

Improved Performance and Durability

"We've been using JSPSEAL's hydraulic cylinder seal kits for our fleet of D61EX-12 bulldozers, and the difference has been remarkable. The seals have significantly reduced hydraulic leaks and improved overall performance, allowing us to operate more efficiently even in tough conditions."

John Smith, Construction Manager

"Our maintenance team switched to JSPSEAL's seal kits after facing frequent downtime due to seal failures. Since then, we've noticed a noticeable increase in seal durability and reliability. It's been a cost-effective solution that has kept our equipment running smoothly."

Sarah Johnson, Maintenance Supervisor

"These seal kits have proven their worth in our operations. They not only meet OEM standards but also exceed our expectations in terms of performance and longevity. Highly recommended for anyone looking to enhance their equipment's reliability."

Michael Lee, Equipment Operator

"Since incorporating JSPSEAL's seal kits into our preventive maintenance program, we've seen a significant decrease in hydraulic issues. The seals have held up well under heavy usage, saving us both time and money."

David Brown, Fleet Manager

These testimonials provide real-world evidence of how JSPSEAL's hydraulic seal kits have positively impacted equipment performance and durability, endorsed by satisfied customers and experienced maintenance professionals.

Optimize Your Equipment's Performance with JSPSEAL

The D61EX-12/D61PX-12 Cylinder Hydraulic Cylinder Seal Kit from JSPSEAL provides essential solutions for maintaining and improving the performance of heavy-duty machinery. Engineered to withstand demanding operational conditions, this kit offers robust sealing solutions that effectively prevent hydraulic leaks and boost efficiency. By incorporating high-quality seals and following best practices in installation and maintenance, operators can significantly extend equipment lifespan and reduce costly downtime. Whether enhancing durability, optimizing hydraulic system function, or ensuring compatibility with specific bulldozer models, JSPSEAL's seal kit ensures consistent reliability and operational integrity in challenging work environments. It represents a trusted solution tailored to enhance longevity and performance, making it a crucial investment for ensuring reliable machinery operation over time. For those aiming to enhance the dependability and efficiency of their heavy-duty equipment, selecting JSPSEAL's Cylinder Hydraulic Cylinder Seal Kit is essential.