If you're in the construction industry, you're likely familiar with Komatsu equipment. Komatsu is a leading manufacturer of construction and mining equipment, and their machines are known for their durability and reliability. One key component of Komatsu equipment is their hydraulic seals, which are essential for ensuring that the equipment operates smoothly and efficiently.

Komatsu seals are designed to withstand the harsh conditions of construction and mining sites. They are made from high-quality materials and are engineered to provide a tight seal that prevents leaks and contamination. Whether you need a seal kit for a lift cylinder or face seals for tread rollers, there are many options available to fit your specific needs.

When it comes to purchasing Komatsu seals, it's important to choose a reputable supplier who can provide you with high-quality products. There are many suppliers out there, but not all of them are created equal. By doing your research and choosing a supplier that specializes in Komatsu seals, you can ensure that you're getting the best possible product for your equipment.

Komatsu Seal Overview

If you own or operate Komatsu heavy equipment, you know how important it is to keep your machinery running smoothly. One crucial component of your equipment is the Komatsu seal. In this section, you'll learn about the history and development of Komatsu seals, as well as the different types and materials available.

History and Development

Komatsu has been a leading manufacturer of heavy equipment for over a century. Over time, they have developed and improved their seals to meet the demands of their customers. Today, Komatsu seals are known for their durability, reliability, and high performance.

Types and Materials

Komatsu seals come in a variety of types and materials to suit different applications. Some of the most common types of Komatsu seals include:

- Cylinder seals

- Face seals

- Rod seals

- Piston seals

- Wiper seals

These seals are made from a variety of materials, including rubber, polyurethane, and other high-performance materials. The choice of material depends on the specific application and the conditions in which the equipment will be used.

Overall, Komatsu seals are an essential component of your heavy equipment. They help to prevent leaks, protect your machinery from dirt and debris, and ensure that your equipment operates at peak performance. Whether you need a cylinder seal, face seal, or another type of seal, Komatsu has a solution that will meet your needs.

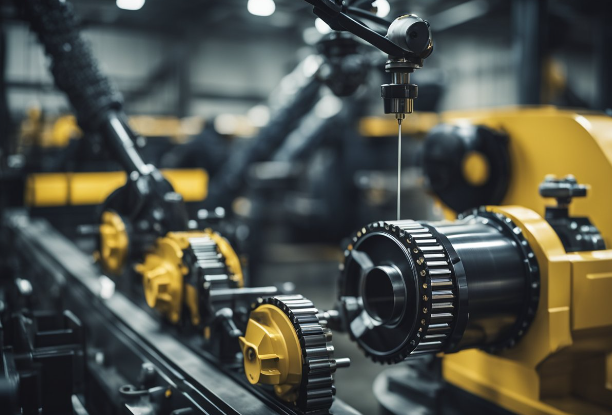

Application in Machinery

Komatsu seals are widely used in various types of machinery, ranging from construction equipment to mining machinery. Here are some of the most common applications of Komatsu seals in different types of machinery:

Construction Equipment

Komatsu seals are commonly used in construction equipment such as excavators, bulldozers, and loaders. These seals are designed to withstand harsh working conditions and prevent hydraulic fluid leaks, which can lead to equipment failure and downtime.

Some of the most common Komatsu seals used in construction equipment include boom cylinder seals, arm cylinder seals, and bucket cylinder seals. These seals are critical components that ensure the smooth operation of hydraulic cylinders, which are responsible for lifting, digging, and pushing heavy loads.

Mining Machinery

Mining machinery operates in extremely harsh environments that expose the equipment to dust, dirt, and debris. Komatsu seals are designed to withstand these conditions and prevent hydraulic fluid leaks, which can cause equipment failure and downtime.

Komatsu seals are commonly used in mining machinery such as excavators, haul trucks, and loaders. These seals are critical components that ensure the smooth operation of hydraulic cylinders, which are responsible for lifting, digging, and transporting heavy loads.

Some of the most common Komatsu seals used in mining machinery include boom cylinder seals, arm cylinder seals, and steering cylinder seals. These seals are designed to withstand high pressures and temperatures, as well as abrasive materials that can cause wear and tear on the equipment.

Overall, Komatsu seals are essential components in various types of machinery, ensuring the smooth operation and preventing costly downtime.

Installation and Maintenance

Installation Guidelines

When installing Komatsu seals, it is important to follow the manufacturer's guidelines to ensure proper installation and prevent premature failure. Here are some general guidelines to follow when installing Komatsu seals:

- Clean the installation surface thoroughly to remove any contaminants that may cause damage to the seal.

- Lubricate the seal with a compatible lubricant to prevent dry running and premature wear.

- Ensure that the seal is installed in the correct orientation to prevent leakage.

- Use the appropriate installation tool to prevent damage to the seal during installation.

- Check for proper fit and alignment before tightening any fasteners.

By following these guidelines, you can ensure that your Komatsu seals are installed correctly and will provide reliable performance.

Maintenance Practices

Proper maintenance is essential to extend the life of your Komatsu seals and prevent premature failure. Here are some maintenance practices to follow:

- Regularly inspect seals for signs of wear, damage, or leakage.

- Replace seals that show signs of wear or damage immediately.

- Use only genuine Komatsu replacement seals to ensure proper fit and performance.

- Follow the manufacturer's recommended maintenance schedule for your equipment to prevent premature seal failure.

- Keep seals clean and free of contaminants that may cause damage.

By following these maintenance practices, you can ensure that your Komatsu seals provide reliable performance and extend the life of your equipment.

Performance and Reliability

When it comes to Komatsu seal performance, two key factors are seal effectiveness and durability. Let's take a closer look at each of these factors.

Seal Effectiveness

The effectiveness of a seal is critical to ensuring that your equipment runs smoothly and efficiently. Komatsu floating seals, for example, are engineered to the highest standards to deliver unparalleled performance and reliability. Designed to meet or exceed OEM specifications, these seals provide exceptional durability, extending the lifespan of your equipment and reducing maintenance costs.

In addition to their durability, Komatsu seals are also designed to provide optimal sealing performance. This means that they can effectively seal against a variety of fluids, including oil, water, and hydraulic fluid. This ensures that your equipment stays free from leaks and contamination, which can cause serious problems over time.

Durability Factors

Another important factor to consider when it comes to Komatsu seals is their durability. Durability is critical to ensuring that your seals can withstand the harsh conditions of your work environment. Komatsu seals are designed with durability in mind, and are made from high-quality materials that can withstand extreme temperatures, pressures, and other environmental factors.

In addition to their materials, Komatsu seals are also designed to be easy to install and maintain. This means that you can quickly and easily replace worn or damaged seals, without having to take your equipment out of commission for extended periods of time.

Overall, Komatsu seals are an excellent choice for anyone looking for high-performance, reliable seals that can withstand even the toughest conditions. With their exceptional durability and sealing performance, these seals are sure to provide many years of reliable service, helping you get the most out of your equipment.

Innovation and Future Trends

As technology continues to advance, Komatsu is committed to staying ahead of the curve with innovative seal solutions. Here are some of the latest trends and advancements in sealing technology that you can expect to see from Komatsu in the future.

Advanced Materials

One of the most significant trends in sealing technology is the use of advanced materials. Traditional sealing materials like rubber and plastics are being augmented by advanced composites, ceramics, and nanomaterials. These materials offer improved durability, wear resistance, and sealing performance, making them ideal for demanding applications.

Seal Design Optimization

Another trend in sealing technology is the optimization of seal design. By using advanced software and simulation tools, Komatsu can optimize the design of seals for specific applications. This results in improved sealing performance, reduced friction, and longer seal life.

Predictive Maintenance

Finally, predictive maintenance is becoming increasingly important in sealing technology. By using sensors and other monitoring tools, Komatsu can predict when a seal is likely to fail and schedule maintenance accordingly. This reduces downtime and extends the life of the seal.

Overall, Komatsu is committed to staying at the forefront of sealing technology. By using advanced materials, optimizing seal design, and implementing predictive maintenance, Komatsu is able to provide customers with seal solutions that are reliable, efficient, and cost-effective.

Frequently Asked Questions

What is the process for replacing a seal in Komatsu equipment?

Replacing a seal in Komatsu equipment involves disassembling the affected area, removing the old seal, cleaning the area, and installing the new seal. It is important to follow the manufacturer's guidelines and use the correct tools for the job.

How can you determine the correct size of a seal for a specific Komatsu machine?

The correct size of a seal for a specific Komatsu machine can be determined by consulting the equipment manual or contacting a Komatsu dealer. It is important to use the correct size seal to ensure proper function and avoid damage to the equipment.

Where can you purchase authentic seals for Komatsu machinery?

Authentic seals for Komatsu machinery can be purchased from authorized Komatsu dealers or distributors. It is important to use authentic seals to ensure proper function and avoid damage to the equipment.

What are the signs that a seal needs to be replaced in Komatsu equipment?

Signs that a seal needs to be replaced in Komatsu equipment include leaking fluids, decreased performance, unusual noises, and visible wear or damage to the seal. It is important to address seal issues promptly to avoid further damage to the equipment.

Are there any special considerations when installing seals in high-pressure areas of Komatsu machines?

When installing seals in high-pressure areas of Komatsu machines, it is important to use the correct seal material and follow the manufacturer's guidelines. It may also be necessary to use special tools and techniques to ensure proper installation and avoid damage to the equipment.

How does the quality of aftermarket seals compare to original Komatsu seals?

The quality of aftermarket seals can vary widely and may not meet the same standards as original Komatsu seals. It is important to use authentic seals to ensure proper function and avoid damage to the equipment. If aftermarket seals are used, it is important to choose a reputable supplier and ensure that the seals meet the manufacturer's specifications.