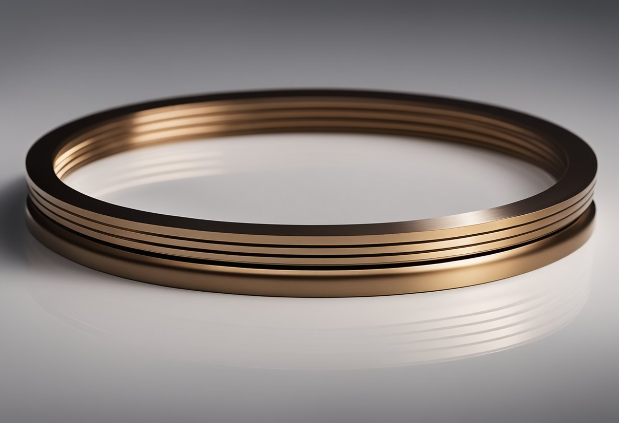

If you are in the market for high-quality piston rings, you may be wondering which type is best for your application. One option to consider is PTFE bronze piston rings. These rings are made from a combination of polytetrafluoroethylene (PTFE) and bronze, resulting in a material that is both durable and low-friction.

PTFE bronze piston rings are known for their ability to withstand high temperatures and pressures, making them ideal for use in engines and other machinery. They are also resistant to chemicals and corrosion, which helps to extend their lifespan. Additionally, because they are low-friction, they can help to reduce wear and tear on the machinery they are used in, which can save you money in the long run.

Overall, PTFE bronze piston rings are a great choice for those looking for a durable, long-lasting, and low-friction option for their machinery. With their ability to withstand high temperatures and pressures, resist chemicals and corrosion, and reduce wear and tear, they are a reliable choice for a wide range of applications.

PTFE Bronze Piston Rings Overview

If you're looking for a piston ring that offers excellent chemical and thermal resistance, high bearing capacity, and low wear, then PTFE Bronze Piston Rings might be the solution you need. These piston rings are made from a combination of polytetrafluoroethylene (PTFE) and bronze, which gives them unique properties that make them ideal for use in a variety of applications.

Properties of PTFE Bronze

PTFE Bronze Piston Rings are known for their excellent chemical and thermal resistance. They have a temperature range from -200°C to +260°C, which makes them suitable for use in extreme conditions. Additionally, they have a high bearing capacity and pressure resistance, which means they can withstand high loads without deforming or breaking.

PTFE Bronze Piston Rings are also known for their low wear. They have a low coefficient of friction, which means they don't generate a lot of heat or wear down quickly. This makes them ideal for use in applications where minimal lubrication is required.

Advantages in Piston Ring Applications

One of the main advantages of PTFE Bronze Piston Rings is their ability to withstand high temperatures and pressures. This makes them ideal for use in engines and other high-performance applications where temperatures and pressures can reach extreme levels.

PTFE Bronze Piston Rings are also known for their low friction and high wear resistance. This means they can last longer than other types of piston rings and require less maintenance.

In addition, PTFE Bronze Piston Rings are suitable for use with non-hardened contact surfaces. This means they can be used with a variety of materials without causing damage or wear.

Overall, PTFE Bronze Piston Rings are a reliable and durable choice for piston ring applications. With their unique combination of properties, they offer excellent performance in a variety of conditions.

Design and Manufacturing

Design Considerations

When designing PTFE bronze piston rings, there are several considerations to keep in mind. First and foremost, the ring must fit snugly against the cylinder wall to ensure efficient sealing. This requires careful consideration of the ring's dimensions, including its thickness, width, and diameter.

Another important consideration is the material used to make the ring. PTFE bronze is a popular choice for its excellent wear resistance, low friction coefficient, and high-temperature tolerance. The addition of bronze to PTFE gives better dimensional stability and lowers creep, cold flow, and wear.

Additionally, the design of the ring should take into account the application in which it will be used. For example, if the ring will be used in a reciprocating compressor, it must be designed to withstand the high pressures and temperatures associated with this type of application.

Manufacturing Processes

The manufacturing process for PTFE bronze piston rings typically involves a combination of molding and machining. The rings are first molded to the desired dimensions and then machined to achieve the necessary tolerances.

During the molding process, the PTFE bronze material is heated and compressed into a mold to form the shape of the ring. Once the ring has cooled and solidified, it is removed from the mold and sent to the machining department.

In the machining department, the ring is carefully machined to the exact dimensions required for its specific application. This includes cutting the ring to the correct width and thickness and ensuring that it has the proper surface finish to ensure efficient sealing.

Overall, the design and manufacturing of PTFE bronze piston rings require careful consideration of a variety of factors to ensure that the rings perform optimally in their intended application.

Application and Performance

Industrial Usage

PTFE bronze piston rings are commonly used in industrial applications where there is a need for low friction, high wear resistance, and good chemical compatibility. These rings are used in a variety of industries, including automotive, aerospace, and food processing.

In the automotive industry, PTFE bronze piston rings are used in engines to reduce friction and wear. The rings are also used in the transmission and other moving parts of the vehicle. In the aerospace industry, PTFE bronze piston rings are used in aircraft engines to improve performance and reliability.

In the food processing industry, PTFE bronze piston rings are used in pumps and other equipment that comes into contact with food. The rings are resistant to chemicals and high temperatures, making them ideal for use in this industry.

Performance Metrics

PTFE bronze piston rings offer several performance benefits, including low friction, high wear resistance, and good chemical compatibility. These rings have a low coefficient of friction, which reduces wear and improves efficiency.

The wear resistance of PTFE bronze piston rings is also high, which means they can withstand high loads and last longer than other materials. The rings are also resistant to chemicals, which makes them suitable for use in harsh environments.

In addition, PTFE bronze piston rings have a low thermal expansion coefficient, which means they maintain their shape and size even when exposed to high temperatures. This makes them ideal for use in high-temperature applications.

Overall, PTFE bronze piston rings are a reliable and effective solution for applications where low friction, high wear resistance, and good chemical compatibility are required.

Maintenance and Durability

When it comes to maintaining PTFE bronze piston rings, there are a few things to keep in mind. First, it is important to regularly inspect the rings for any signs of wear or damage. If you notice any cracks, chips, or other damage, it is important to replace the rings as soon as possible to prevent further damage to your equipment.

In addition to regular inspections, it is also important to keep the rings clean and free of debris. Dirt, dust, and other contaminants can cause the rings to wear down more quickly, so it is important to clean them regularly using a soft cloth or brush.

When it comes to durability, PTFE bronze piston rings are known for their long-lasting performance. The combination of PTFE and bronze provides excellent wear resistance and high load-carrying capacity, making them ideal for use in a wide range of applications.

That being said, it is important to choose the right type of ring for your specific application. Factors such as operating temperature, pressure, and chemical compatibility can all impact the performance and durability of the rings, so it is important to consult with a knowledgeable supplier to ensure that you are selecting the right rings for your needs.

Overall, with proper maintenance and the right selection of rings, PTFE bronze piston rings can provide reliable and long-lasting performance in a variety of applications.