PTFE Guide Rings: A Comprehensive Guide to Their Properties and Applications

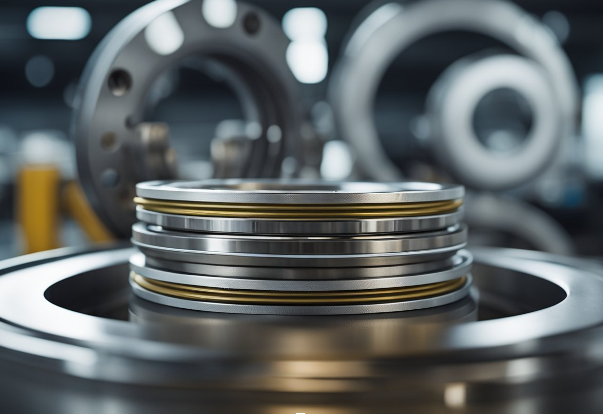

If you're in the market for hydraulic cylinder components, you may have come across PTFE guide rings. These rings are designed to guide the piston and rod of a hydraulic cylinder, absorbing lateral forces and preventing metal-on-metal contact between moving parts. With a high bearing load capacity and low friction, PTFE guide rings are a popular choice for many applications.

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer that is known for its non-stick properties and resistance to heat and chemicals. When used in guide rings, PTFE can help reduce wear and tear on hydraulic cylinders, leading to longer service life and improved performance. Additionally, PTFE guide rings are often self-lubricating, which can further reduce friction and improve efficiency.

Understanding PTFE Guide Rings

PTFE guide rings are non-metallic components designed to guide the piston and rod of a hydraulic cylinder. They are commonly used in applications where metal-on-metal contact between the cylinder's moving parts, such as the piston and the cylinder or the rod and the cylinder head, can cause excessive wear and tear, leading to premature failure of the hydraulic system.

Properties of PTFE

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. It is a high-performance material that is known for its excellent chemical resistance, low coefficient of friction, and high temperature tolerance. These properties make PTFE an ideal material for use in hydraulic systems, where it can withstand harsh operating conditions and provide reliable performance over an extended period of time.

Function of Guide Rings

The primary function of PTFE guide rings is to provide a low-friction surface for the piston and rod to slide against, reducing wear and tear on the cylinder and prolonging the life of the hydraulic system. Guide rings also help to absorb lateral forces, ensuring that the piston and rod remain properly aligned and reducing the risk of damage to the system.

In addition to their low-friction properties, PTFE guide rings are also resistant to a wide range of chemicals and can withstand high temperatures without degrading or losing their shape. This makes them ideal for use in applications where the hydraulic system may be exposed to harsh chemicals or extreme temperatures.

Overall, PTFE guide rings are an essential component of any hydraulic system, providing reliable performance and prolonging the life of the system. By choosing high-quality guide rings made from PTFE, you can ensure that your hydraulic system will operate smoothly and efficiently for years to come.

Design and Material Specifications

When it comes to designing PTFE guide rings, there are certain standard sizes and tolerances that you should be aware of. These specifications vary depending on the application, but generally, guide rings have an inner diameter ranging from 6mm to 500mm, with a thickness of 1mm to 10mm. The outer diameter can range from 10mm to 600mm. The tolerances for these dimensions depend on the specific application and the manufacturing process used.

Standard Sizes and Tolerances

PTFE guide rings come in a variety of standard sizes and tolerances. The most common sizes are based on standard metric and imperial measurements. The tolerances for these sizes are usually specified by the manufacturer and depend on the specific application. For example, a guide ring used in a hydraulic cylinder may have different tolerances than one used in a pneumatic cylinder.

Material Grades and Composites

PTFE guide rings are typically made from a variety of materials, including pure PTFE, filled PTFE, and composites. The choice of material depends on the specific application and the operating conditions. Pure PTFE is suitable for use in low-pressure applications and is resistant to most chemicals. Filled PTFE, which contains fillers such as glass or carbon, is suitable for use in high-pressure applications and is more wear-resistant than pure PTFE. Composites, which are made from a combination of materials, offer a balance of properties and are suitable for use in a wide range of applications.

When selecting a material for your PTFE guide ring, it is important to consider factors such as temperature, pressure, and chemical compatibility. You should also consider the specific requirements of your application, such as wear resistance and friction. By choosing the right material and design specifications for your PTFE guide ring, you can ensure optimal performance and longevity.

Installation and Maintenance

Installation Procedures

Installing PTFE guide rings is a straightforward process that can be accomplished with basic tools. Before installation, ensure that the cylinder bore is clean and free of debris. Then, follow these steps:

- Apply a light coat of hydraulic oil to the guide ring and the cylinder bore.

- Gently slide the guide ring into the cylinder bore, ensuring that it is properly aligned.

- Use a guide ring installation tool to push the guide ring into place. Do not use excessive force, as this can damage the guide ring.

Maintenance Tips

Proper maintenance is essential for ensuring the longevity and performance of PTFE guide rings. Here are some tips to keep in mind:

- Regularly inspect the guide rings for signs of wear or damage. If any issues are found, replace the guide ring immediately.

- Clean the guide rings and cylinder bore regularly to prevent the buildup of debris or contaminants.

- Ensure that the hydraulic system is properly lubricated to minimize friction and wear on the guide rings.

- Follow the manufacturer's recommended service intervals for the hydraulic system to ensure that all components, including the guide rings, are in good working order.

By following these installation and maintenance procedures, you can ensure that your PTFE guide rings function properly and last for a long time.

Applications of PTFE Guide Rings

PTFE guide rings are versatile components that are used in a wide range of industrial and specialized applications. In this section, we will discuss the most common applications of PTFE guide rings, including their use in industrial settings and specialized applications.

Industrial Uses

PTFE guide rings are commonly used in industrial applications, particularly in hydraulic and pneumatic systems. They are used to guide pistons and rods, providing support and reducing friction. PTFE guide rings are also used in reciprocating pumps, compressors, and other machinery that requires precise movement and high resistance to wear.

PTFE guide rings are particularly well-suited for use in harsh environments, such as those found in the oil and gas industry. They are resistant to chemicals, high temperatures, and extreme pressures, making them ideal for use in drilling equipment, pumps, and valves.

Specialized Applications

PTFE guide rings are also used in specialized applications that require unique properties. For example, PTFE guide rings are used in the aerospace industry to guide fuel and hydraulic lines. They are also used in the medical industry to guide surgical instruments and provide support for medical devices.

In addition, PTFE guide rings are used in the food and beverage industry, where they provide support and reduce friction in processing equipment. They are also used in the automotive industry, where they are used to guide pistons and rods in engines and transmissions.

Overall, PTFE guide rings are a versatile component that is used in a wide range of industrial and specialized applications. Their unique properties make them ideal for use in harsh environments and applications that require precise movement and high resistance to wear.

Performance and Limitations

Temperature and Pressure Limits

PTFE guide rings are known for their exceptional resistance to high temperatures and pressures. They can withstand temperatures ranging from -200°C to +260°C and pressures of up to 10,000 psi. This makes them suitable for use in a wide range of applications, including those involving harsh environments.

However, it is important to note that PTFE guide rings have a lower load-carrying capacity compared to other materials. As such, they may not be suitable for use in applications with high loads or where the pressure is likely to fluctuate rapidly. In such cases, it may be necessary to consider alternative materials such as thermoset wear rings.

Wear and Lifespan Considerations

PTFE guide rings are known for their excellent wear resistance, which makes them ideal for use in applications involving high-speed rotation or reciprocating motion. They are also highly resistant to abrasion and chemical attack, which helps to prolong their lifespan.

However, it is important to note that PTFE guide rings can be prone to cold flow, which can cause them to deform over time. This can lead to a loss of sealing effectiveness and may necessitate the replacement of the guide ring. To mitigate this, it is recommended to use a guide ring with a backup ring or a guide ring made from a harder material.

Overall, PTFE guide rings are an excellent choice for use in applications involving high temperatures and harsh environments. However, it is important to consider their limitations and to choose the appropriate material and design for your specific application.