If you are in the market for high-quality seals for your hydraulic system, you may have come across PTFE piston rod seals and backup rings. These components are essential in ensuring that your hydraulic system operates smoothly and efficiently.

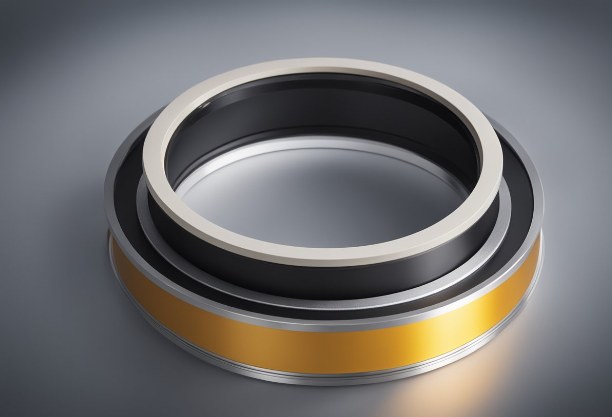

PTFE (polytetrafluoroethylene) is a synthetic material that offers excellent chemical resistance, low friction, and high-temperature resistance. These properties make PTFE an ideal material for piston rod seals and backup rings. The piston rod seal is responsible for preventing fluid leakage from the hydraulic cylinder, while the backup ring is designed to prevent extrusion of the seal under high-pressure conditions.

When selecting PTFE piston rod seals and backup rings, it is important to consider factors such as the operating temperature, pressure, and fluid compatibility. Additionally, the design of the seal and backup ring should be optimized for your specific application to ensure maximum performance and longevity. With the right PTFE seals and backup rings, you can minimize downtime, reduce maintenance costs, and improve the overall efficiency of your hydraulic system.

PTFE Piston Rod Seals

Design and Function

PTFE piston rod seals are designed to provide a reliable sealing solution for high-pressure hydraulic systems. They are used to prevent fluid leakage between the piston rod and the cylinder bore. The seals are typically installed in a groove on the piston rod and are pressed against the cylinder bore by the hydraulic pressure.

The design of PTFE piston rod seals is critical to their performance. The seal must be able to withstand high pressure and temperature while maintaining a tight seal. The seal must also be able to accommodate the movement of the piston rod as it travels back and forth in the cylinder bore.

Material Properties

PTFE is a commonly used material for piston rod seals because of its excellent chemical resistance and low friction coefficient. PTFE has a low coefficient of friction, which reduces wear and tear on the seal and improves the performance of the hydraulic system.

PTFE piston rod seals are also known for their ability to withstand high temperatures and pressures. They are resistant to most chemicals and can be used in a variety of applications.

In addition to PTFE, other materials such as elastomers and thermoplastics can be used for piston rod seals. The choice of material depends on the specific application requirements.

Overall, PTFE piston rod seals provide a reliable and effective sealing solution for high-pressure hydraulic systems. Their design and material properties make them suitable for use in a wide range of applications.

Backup Ring Significance

Role in Sealing Systems

Backup rings play a crucial role in sealing systems by providing support to the primary seal and closing off the extrusion gap. They are typically made of a harder material than the seal itself and are used in high-pressure applications where the seal is subjected to extrusion forces. Backup rings prevent the seal from extruding into the gap between the sealing surfaces and maintain the integrity of the seal.

Compatibility and Selection

When selecting a backup ring, it is important to consider the environment and the degree of acceptable friction losses. The backup ring must be compatible with the seal material and the fluid being sealed. Additionally, the backup ring should have the same or higher hardness than the seal material to prevent the backup ring from extruding into the gap.

PTFE backup rings are commonly used in sealing systems due to their excellent chemical resistance, low friction, and high-temperature capabilities. PEEK backup rings are also used in high-temperature and high-pressure applications where PTFE is not suitable. When selecting a backup ring, it is important to consult with a knowledgeable supplier to ensure that the backup ring is compatible with the seal material and the application requirements.

In summary, backup rings play a significant role in sealing systems by providing support to the primary seal and preventing extrusion into the gap. When selecting a backup ring, it is important to consider the environment, the degree of acceptable friction losses, and the compatibility with the seal material and fluid being sealed. PTFE and PEEK backup rings are commonly used in high-temperature and high-pressure applications.

Installation and Maintenance

Installation Best Practices

Proper installation of PTFE piston rod seals and backup rings is essential for optimal performance and longevity. Here are some best practices to follow during installation:

- Thoroughly clean and inspect the sealing surface and groove before installation to ensure there are no defects or debris that could compromise the seal.

- Lubricate the sealing surface and backup ring with a compatible lubricant to aid in installation and prevent damage to the seal.

- Use appropriate tools and equipment to avoid damaging the seal during installation. Avoid using sharp or pointed tools that could scratch or cut the seal.

- Ensure the seal and backup ring are properly positioned in the groove and do not overlap or twist during installation.

- Apply the recommended pre-load to the seal and backup ring, if applicable, to ensure proper sealing and prevent extrusion.

Maintenance Guidelines

Proper maintenance of PTFE piston rod seals and backup rings is necessary to ensure long-term performance and prevent premature failure. Here are some guidelines to follow for maintenance:

- Regularly inspect the seals and backup rings for signs of wear, damage, or leakage. Replace any damaged or worn components immediately.

- Check the sealing surface and groove for defects or debris that could compromise the seal. Clean and repair as necessary.

- Ensure the seal and backup ring are properly lubricated to prevent excessive friction and wear.

- Monitor the operating conditions of the seal and backup ring, including temperature, pressure, and speed, to ensure they are within the recommended range.

- Follow the manufacturer's recommendations for maintenance intervals and procedures to ensure optimal performance and longevity.

By following these installation and maintenance best practices, you can ensure your PTFE piston rod seals and backup rings perform at their best for a long time.