If you're in the market for a wiper seal, you may want to consider a urethane wiper seal. These seals are designed to protect hydraulic systems from dirt, dust, and other contaminants that can cause damage to the system. Urethane wiper seals are known for their durability and long lifespan, making them a popular choice for many industrial applications.

One of the key benefits of urethane wiper seals is their ability to withstand extreme temperatures and pressures. This makes them ideal for use in heavy-duty applications where other seals may fail. Additionally, urethane wiper seals are resistant to many chemicals, oils, and solvents, further increasing their lifespan and durability.

If you're looking for a wiper seal that can provide reliable protection for your hydraulic system, a urethane wiper seal may be the right choice for you. With their durability, resistance to extreme conditions, and chemical resistance, these seals can help keep your system running smoothly for years to come.

Overview of Urethane Wiper Seals

Definition and Purpose

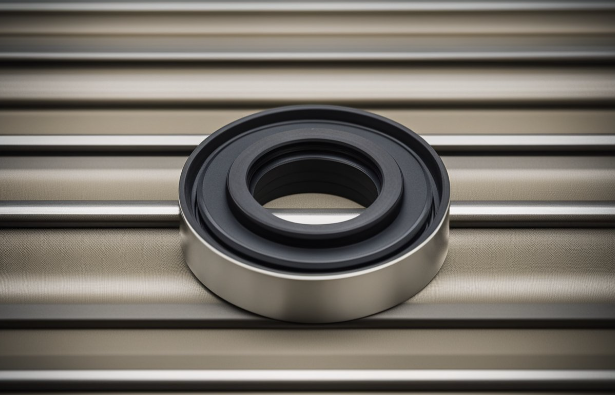

Urethane wiper seals are high-performance sealing products used in a wide range of industrial applications. These seals are designed to maintain sealing contact to the piston rod when the equipment is in use, preventing contaminants from entering the cylinder. They are typically made of molded high-grade urethane and are compatible with MS-28776 (MS-33675) dash-size grooves.

The purpose of urethane wiper seals is to provide unparalleled durability and reliability, even in extreme temperatures and pressures. They are ideal for use in light to medium-duty hydraulic applications where durability and resilience are required.

Advantages of Urethane

Urethane wiper seals offer several advantages over other sealing products. Some of these advantages include:

- Durability: Urethane is a highly durable material that can withstand extreme temperatures and pressures, making it an ideal choice for industrial applications.

- Resilience: Urethane wiper seals are highly resilient, which means they can recover their shape after being compressed or stretched.

- Low Friction: Urethane has a low coefficient of friction, which means it can reduce wear and tear on equipment, leading to longer service life.

- Chemical Resistance: Urethane is resistant to a wide range of chemicals, making it an ideal choice for use in harsh environments.

- Easy Installation: Urethane wiper seals are easy to install and require minimal maintenance, which can save time and money in the long run.

Overall, urethane wiper seals are a reliable and cost-effective sealing solution for a wide range of industrial applications.

Design Considerations

Material Properties

When designing a urethane wiper seal, it is important to consider the material properties of the urethane. Urethane is known for its excellent abrasion resistance, high tensile strength, and good tear resistance. However, it is also sensitive to temperature and chemical exposure. Therefore, it is important to choose a urethane material that is compatible with the fluid being sealed and the operating temperature range.

Seal Profiles

Another important consideration when designing a urethane wiper seal is the seal profile. The seal profile determines the sealing function and performance of the seal. There are several types of seal profiles available for urethane wiper seals, including single lip, double lip, and triple lip designs. The choice of seal profile depends on the application requirements, such as the level of contamination and the operating speed.

Dimensional Tolerances

Dimensional tolerances are also critical when designing a urethane wiper seal. The seal must fit tightly around the rod or shaft to prevent fluid leakage and contamination. However, the seal must also have enough clearance to allow for thermal expansion and contraction. Therefore, it is important to carefully consider the dimensions of the seal and the mating surface.

In summary, when designing a urethane wiper seal, it is important to consider the material properties, seal profiles, and dimensional tolerances. By carefully selecting the appropriate material and seal profile, and ensuring proper dimensional tolerances, you can ensure optimal sealing performance and long-term reliability.

Application Scenarios

Industrial Usage

Urethane wiper seals are widely used in industrial applications to protect hydraulic and pneumatic systems from contamination. These seals are designed to scrape dirt, dust, and other foreign particles from the rods of hydraulic cylinders, preventing them from entering the system and causing damage. They are commonly used in heavy-duty machinery, such as construction equipment, mining machinery, and agricultural machinery.

Urethane wiper seals are ideal for industrial applications because of their excellent mechanical properties, including high tensile strength and outstanding tear and abrasion resistance. They are also resistant to oil and fuel, making them suitable for use in hydraulic systems that operate with oil-based hydraulic fluids.

Hydraulic Systems

Hydraulic systems are used in a variety of applications, including construction equipment, agricultural machinery, and industrial machinery. These systems rely on hydraulic cylinders to generate power, and urethane wiper seals play a crucial role in protecting these cylinders from contamination.

Urethane wiper seals are designed to scrape dirt, dust, and other foreign particles from the rods of hydraulic cylinders, preventing them from entering the system and causing damage. They are available in a range of sizes and configurations to fit different types of hydraulic cylinders.

Pneumatic Systems

Pneumatic systems are used in a variety of applications, including manufacturing, automation, and transportation. These systems rely on pneumatic cylinders to generate power, and urethane wiper seals play a crucial role in protecting these cylinders from contamination.

Urethane wiper seals are designed to scrape dirt, dust, and other foreign particles from the rods of pneumatic cylinders, preventing them from entering the system and causing damage. They are available in a range of sizes and configurations to fit different types of pneumatic cylinders.

In summary, urethane wiper seals are an essential component of hydraulic and pneumatic systems, protecting them from contamination and ensuring their smooth operation. They are commonly used in industrial applications, hydraulic systems, and pneumatic systems.

Installation Guidelines

Installing a urethane wiper seal is a crucial step in ensuring the optimal performance of your hydraulic system. Here are some general guidelines to follow during installation:

Housing Design

The design of the housing for the wiper seal can affect its performance. The two most common housing designs are open and stepped housings. Open housings have a simple design and are easy to install. They consist of a bore with a groove for the wiper seal. Stepped housings, on the other hand, have a more complex design and require more precise installation. They consist of a bore with a step that holds the wiper seal in place.

Seal Orientation

The orientation of the wiper seal during installation is important. The lip of the seal should face the fluid being sealed. This ensures that the seal is in contact with the fluid and is able to wipe away any contaminants.

Seal Lubrication

Urethane wiper seals do not require lubrication, but it is recommended to use a small amount of hydraulic oil or grease on the seal lip during installation. This helps to reduce friction and prevent damage to the seal during installation.

Seal Installation

When installing the wiper seal, it is important to ensure that it is properly seated in the housing groove. Use a seal installation tool or a soft-faced hammer to gently tap the seal into place. Do not use a sharp object or excessive force, as this can damage the seal.

By following these installation guidelines, you can ensure that your urethane wiper seal is installed correctly and will provide optimal performance for your hydraulic system.

Maintenance and Replacement

Inspection Procedures

To ensure the optimal performance of your urethane wiper seal, you should inspect it regularly. Inspections should be conducted at least once every six months, or as recommended by the manufacturer. It is important to inspect the seal for any signs of damage, such as cracks, cuts, or tears, as well as any signs of wear, such as flattening or hardening.

When inspecting the seal, make sure to clean the surface thoroughly to remove any dirt, debris, or other contaminants. Use a soft cloth or sponge and a mild detergent to clean the surface. Avoid using harsh chemicals or abrasive materials that could damage the surface of the seal.

Lifespan and Wear Factors

The lifespan of a urethane wiper seal depends on a variety of factors, including the operating conditions, the frequency of use, and the quality of the seal. In general, a well-maintained seal can last for several years, while a poorly maintained seal may need to be replaced more frequently.

Factors that can contribute to wear and tear on the seal include exposure to extreme temperatures, exposure to chemicals or other corrosive substances, and exposure to high levels of friction or pressure. To extend the lifespan of your seal, it is important to take steps to minimize these factors.

When it comes time to replace your urethane wiper seal, make sure to choose a high-quality replacement that is designed to meet the specific needs of your application. Look for a seal that is made from high-quality materials and that is designed to withstand the operating conditions of your equipment.

In summary, regular inspections and proper maintenance can help extend the lifespan of your urethane wiper seal. When it comes time to replace the seal, choose a high-quality replacement that is designed to meet the specific needs of your application.