Advantages:

-Good chemical resistance and wear resistance

-Very good low pressure stability.

-Very low compression set due to V-ring

-Simple grove design, simple installation

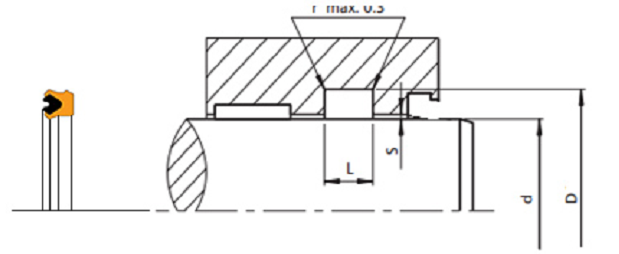

| ITM | ID | OD | L |

| JSURA | 50 | 60 | 6 |

| JSURA | 55 | 65 | 6 |

| JSURA | 60 | 70 | 6 |

| JSURA | 65 | 75 | 6 |

| JSURA | 70 | 80 | 6 |

| JSURA | 75 | 85 | 6 |

| JSURA | 80 | 90 | 6 |

| JSURA | 55 | 65 | 8 |

| JSURA | 65 | 75 | 8 |

| JSURA | 50 | 65 | 9 |

| JSURA | 55 | 65 | 9 |

| JSURA | 55 | 70 | 9 |

| JSURA | 60 | 75 | 9 |

| JSURA | 65 | 80 | 9 |

| JSURA | 70 | 85 | 9 |

| JSURA | 75 | 90 | 9 |

| JSURA | 80 | 95 | 9 |

| JSURA | 85 | 100 | 9 |

| JSURA | 90 | 105 | 9 |

| JSURA | 95 | 110 | 9 |

| JSURA | 100 | 115 | 9 |

| JSURA | 105 | 120 | 9 |

| JSURA | 110 | 125 | 9 |

| JSURA | 115 | 130 | 9 |

| JSURA | 120 | 135 | 9 |

| JSURA | 95 | 115 | 9 |

| JSURA | 50 | 63 | 10 |

| JSURA | 60 | 73 | 10 |

| JSURA | 55 | 68 | 10 |

| JSURA | 60 | 75 | 10 |

| JSURA | 65 | 78 | 10 |

| JSURA | 70 | 83 | 10 |

| JSURA | 80 | 93 | 10 |

| JSURA | 75 | 88 | 10 |

| JSURA | 70 | 85 | 10 |

| JSURA | 75 | 90 | 10 |

| JSURA | 80 | 95 | 10 |

| JSURA | 85 | 100 | 10 |

| JSURA | 90 | 105 | 10 |

| JSURA | 95 | 110 | 10 |

| JSURA | 100 | 115 | 10 |

| JSURA | 105 | 120 | 10 |

| JSURA | 100 | 120 | 10 |

| JSURA | 110 | 130 | 10 |

| JSURA | 120 | 140 | 10 |

| JSURA | 55 | 75 | 12 |

| JSURA | 60 | 80 | 12 |

| JSURA | 65 | 85 | 12 |

| JSURA | 70 | 90 | 12 |

| JSURA | 75 | 95 | 12 |

| JSURA | 85 | 100 | 12 |

| JSURA | 85 | 105 | 12 |

| JSURA | 90 | 110 | 12 |

| JSURA | 95 | 110 | 12 |

| JSURA | 95 | 115 | 12 |

| JSURA | 100 | 120 | 12 |

| JSURA | 105 | 125 | 12 |

| JSURA | 110 | 130 | 12 |

| JSURA | 115 | 135 | 12 |

| JSURA | 120 | 140 | 12 |

| JSURA | 130 | 150 | 12 |

| JSURA | 105 | 125 | 15 |

| JSURA | 115 | 135 | 16 |

| JSURA | 130 | 150 | 16 |

What are JSPSEAL Hydraulic Seal made from?

Hydraulic seals can be made from a variety of materials such as polyurethane, rubber or PTFE ect. The type of material is determined by the specific operating conditions or limits due to seal type, pressure, fluid chemical compatibility, speed, surface roguhness, Radial load, Hydraulic shock, or temperature.

Material Characteristics

| Material | Temperature | Media | Velocity | Pressure(MPa) |

| NBR | -45°C to +140°C | Mineral oil baed, hydraulic fluids,biological degradable oils water | 0.5 | 25 |

| FKM | -20°C to +200°C | Mineral oil baed | 0.5 | 25 |

| PU | -30°C to +100°C | Mineral oil baed, hydraulic fluids | 0.8 | 35 |

| TPE | -40°C to +110°C | Mineral oil baed | 0.8 | |

| POM | -45°C to +120°C | Mineral oil baed | 0.8 | |

| PA | -45°C to +120°C | Mineral oil baed | 1.0 | |

| PTFE | -55°C to +200°C | Mineral oil baed,biological degradable oils water | 15 | 40 |

| PHENOLIC RESIN COTTON FABRIC | -50°C to +120°C | Mineral oil baed,biological degradable oils water | 1.0 |

JSPSEAL aims at win-win situation with China customer. We’re able to improve customer competitiveness with our product and service.

Why Choose JSPSEAL Seal part?

We have been selling in the aftermarket for nearly 20 years, we know more about what kind of seal the machine needs under bad work conditions. And precision molds ensure product size. Original imported raw materials ensure the mechanical properties of the products.

JSPSEAL products have been exported for more than 10 years, and our extensive export experience can help you solve various transportation problems.we can ensure fast and efficient lead times across all JSPSEAL Parts.